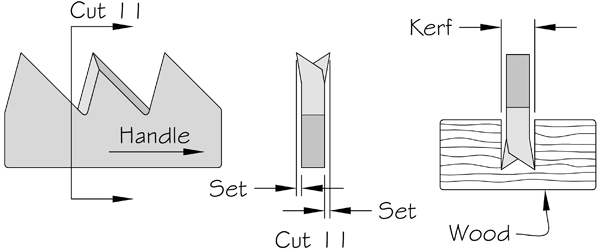

well now im going to have to get my pea brain working. they way i see it is that the cutter is moved forward and as the tooth wears out the angle does change a little and i run this through my head all the time because it makes sense and thats where i get into trouble. the geometery of the tooth changes as it goes from front to back too. so what i think is that two or three things are happeningas the tooth get shorter the front of it goes further down on the arc which changes the overall angle of the tooth. but the tooth itself slopes back as it gets shorter too. i think to maintain the exact inside angles the tooth need to move forward and up at the same time. i have tried to measure the inside angles and have not been successfull yet and i have heard there is some fancy machine that can do it but they arent used that much any more and ant remember what they are called at the moment because im not a spring chicken any more and cant recall it. i have tried measuring photos and physically doing it but its so small its not possible with my tired eyes and lack of tools. back to the profile i have a chain somewhere that i used for playing with the set up on if i can find it. it has teeth of many different length that show the changes quite well. im kind of a perfectionist and spent a lot of time trying to get the grinder to be exaxtly the zame on both sides because i could see that it wasnt. that is also when i dis overed that new chain cutters were not the same from one side to the other. im too anal for my own good sometimes