- Local time

- 7:26 PM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,681

- Reaction score

- 38,418

- Location

- Extreme Southeast CA

My std bar with stihl NK helps keep me from getting pinched. Bars slide out easier than chains.

That’s one of my ‘standard’ methods for removing a pinched saw:My std bar with stihl NK helps keep me from getting pinched. Bars slide out easier than chains.

She cuts eh ,Yes that is correct the kerf gets narrower as the cutters are sharpened and length is reduced.

We have all run a saw and a few sharpens in as the kerf is reduced and the chain hits that sweet spot the perfect load to power ratio.

I don't believe the kerf gets that narrow at the end of the chains life the rivets and bar start binding well at least I've never experienced it personally.

If the cutter in front has done it's job and has the same set as the one behind it the side of the rakers shouldn't be rubbing against the kerf? I see no benefit in trying to make a cutter cut further sideways the cutter would have to tilt to achieve this would wear out the bar groove in no time I'd imagine? But I could be wrong never messed with filing the sides of rakers myself.

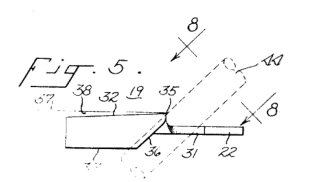

Back to sharpening to suit the wood. This is a Stihl 36RS cutter, sharpened using the older style of sharpening recommend by Stihl decades ago.

Stihl 3/8 file guide, 3/16 file as recommended because it's file more than half way back. File guide at 30 degrees across, 10 degrees of tilt.

Side plate angle is 80 degrees

Top plate cutting angle is 60.

Look at the witness mark. They might tell you to have it 30/60/60 but they mark the f'ing thing with a 80 degree side plate angle.

View attachment 437340

Yes that is correct the kerf gets narrower as the cutters are sharpened and length is reduced.

We have all run a saw and a few sharpens in as the kerf is reduced and the chain hits that sweet spot the perfect load to power ratio.

I don't believe the kerf gets that narrow at the end of the chains life the rivets and bar start binding well at least I've never experienced it personally.

Race chain makers have all kinds of ‘secret sauce’ type things they do make their chains special.

But for us mortals, I believe that a chain loop with its cutters worn back behind the witness mark will still carve a kerf wide enough for the chain and bar to pass through.

Janka:

PNW

Doug fir 660 (fibrous, lot of drag on the back chain robs hp, square ground helps)

Madrone 1460

Alder 590

Big leaf maple 850

Central/east US

Rock maple 1450

Black locust 1700

Osage orange 2620

Pignut hickory 2140

Red oak 1220

White oak 1350

Bur oak 1360

Pin oak 1500

Swamp white oak 1600

Ash 1350

Wall nut 1010

Turkey oak 1200

Southwest US

Monterey pine 710 not hard of fibrous but very stringy. Very hard springy tough once sap desert dried.

Live oak 2680 tough when green, chain skating hard when desert dried.

Alligator juniper 1160 “softwood”

Desert ironwood 3260 (74lb/cu ft, doesn’t float)

Olive 2700

Mesquite 2340 tough when green, hard when dry

Borrowed from Oz : not so hard when green

River red gum euc 2160

Iron bark Euc 2600-3600

Blue gum 2680

Oz:

Buloke 5060 !!!

Yellow box 2930

Gray box 3310

That site is where I got all my numbers from.These guys have compiled a database of properties of various woods, including some that may be more decisive of the forces needed for cutting than just hardness or density.

World's Strongest Woods | The Wood Database

www.wood-database.com

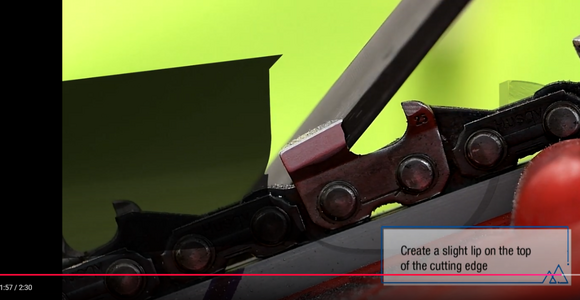

I have tried so many times to contact Vallorbe but have had no luck. Maybe it's the language barrier but I always wanted to know why they leave the side beak. I have filed just like that and it works, I just don't understand why.I was just watching this video from Vallorbe Swiss files and noticed a little bit of 'side nip' on the depth gauge. I was told of this technique in the early 1990's by a Stihl Tech out of Virginia Beach named Brian. Brian had come out to help me set up my USG Square Grinding attachment and we spent a few hours running saws, Stihl of course. Brian's theory was the side of the depth gauge prevented the tooth from leaning over into the work just a little bit. It seems changing the filing angle as suggested above by el33t must let the tooth move out just a little, too. If it didn't I don't see how a wider kerf would result.

Here's a still shot from the Vallorbe Swiss video.

View attachment 437534

Here's the whole video.

What's it all mean? LOL.

The way they file is just insane to me. Dig in with a 4.8mm file and then come back with a small rectangle file to add even more of a beak in 46RM chain. It obviously works for them.I'll see if I can find the vid of one them guys in the jungle free hand ripping out boards with an 070. He takes a pair of pliers and snapped off all the rakers! He's cut's and kerf were dead straight and smooth.

I'm unconvinced rakers have anything to do with controlling kerf width? If everything is in order a cutter should stand up straight in use. Any tilting sideways or the like would promote fast excessive wear of chain and bar I'd imagine?

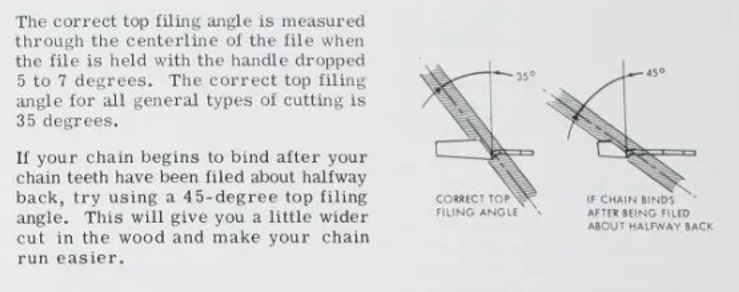

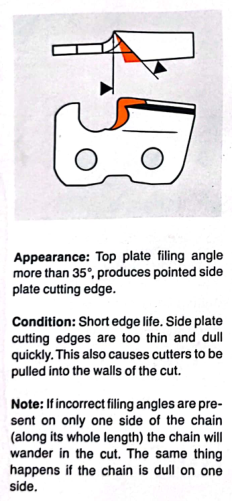

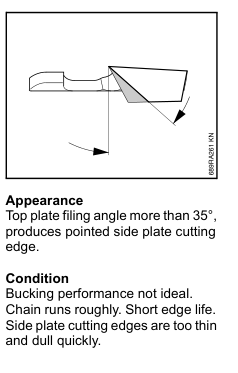

I think the filing angle causes them to wonder side to side more and that's why dropping them to 0 or 10 degrees for milling cleans up the cut surface. If you try 35 or 45 it cuts big lines in the side of the kerf as the cutters try to pull sideways more

I'll see if I can find the vid of one them guys in the jungle free hand ripping out boards with an 070. He takes a pair of pliers and snapped off all the rakers! He's cut's and kerf were dead straight and smooth.

I'm unconvinced rakers have anything to do with controlling kerf width? If everything is in order a cutter should stand up straight in use. Any tilting sideways or the like would promote fast excessive wear of chain and bar I'd imagine?

No advice on chains but if you look at the previous post, apparently bare foot with no hearing protection is the goAny of you guys have experience ripping fence posts? It's been years since I had to do it and now I'm about to start again.

Any chain advice? I used to make a poor man's skip chain by grinding off cutter pairs and it seemed to work better. Not sure if that's the right move or not. Have a couple of hundred to cut.

Not looking forward to ripping yellow box but nearly died when I got the price for star posts

I have to give them some credit, I did some milling last week and it's crap cutting dry wood. Got sick of it quickly and thought I would try ripping boards like they do. It's so much faster and more efficient. I didn't follow their example completely, I had boots, pants and ear muffs, but it's so much easier on the saw.No advice on chains but if you look at the previous post, apparently bare foot with no hearing protection is the go

Yeah we forget how privileged we are living in Australia not having to run an 070 ripping boards to feed our family's.No advice on chains but if you look at the previous post, apparently bare foot with no hearing protection is the go

No advice on ripping posts last time I did that was over 15 years ago ripped 300 used a 066 with 404 RS and 20in hard nosed bar.I have to give them some credit, I did some milling last week and it's crap cutting dry wood. Got sick of it quickly and thought I would try ripping boards like they do. It's so much faster and more efficient. I didn't follow their example completely, I had boots, pants and ear muffs, but it's so much easier on the saw.

I need some practise but I think that way is a lot better if your just cutting dimensional lumber like 6 X 2. The hardnose bars seem to work better because the chain stays in the grove at the nose, the sprocket lifts it up and it wonders a little. I have been watch more of these types of videos now trying to pick up what they are doing. They run a cutter pair sharpened normally (46RM, 10, 80 side plate) followed by a cutter pair that's filed extremely low with the top plate hanging way out (40 degree side plate). The ones I watched still had the depth gauge on the chain. Looked to be set lower than normal but still there.

Might give it a try and see how it works. I was able to cut twice as many boards per tank of fuel compared to running in the mill and you could potentially use a smaller saw because you are only cutting with the last 4 to 10 inches of the bar. Big bars look to help to keep the cuts straight but I was able to do some smaller 4 inch boards with a 45cc saw and 16" bar

These guys are making me want to get a 070 and harden up. The output they get is f'ing incredibleNo advice on ripping posts last time I did that was over 15 years ago ripped 300 used a 066 with 404 RS and 20in hard nosed bar.

IDK what the pros use it's something I try avoid doing ripping posts lol

And yeah the dudes with their 070's ripping boards put westerners with their chainsaw mills to shame lol

Very skilled at what they do.