Philbert

Chainsaw Enthusiast

- Local time

- 9:40 AM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 5,053

- Reaction score

- 21,652

- Location

- East Dakota

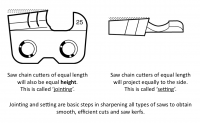

‘Setting’ each tooth or cutter is necessary because the kerf has to be wider than the blade (conventional saws) or guide bar (chainsaws), or the saw will get stuck.

Similarly, ‘jointing’ each tooth or cutter is necessary so that the cutting edges all align at the same height (or along a curve, etc.).

Applies to all wood and metal cutting saws (except some specialty stuff).

The genius of Joe Cox’s design, some 75 years ago, is that you can:

- sharpen the top plate cutting edge;

- sharpen the side plate cutting edge;

- joint the chain;

- set the cutters;

all in one pass of a round file, by keeping the cutters equal length!

You have to sharpen an old fashioned crosscut saw (‘misery whip’) to really appreciate this.

Chains that have cutters at different height, and with different set, will still cut, but not as efficiently. It’s like driving a car with different pressure in each of the four tires.

Philbert

Similarly, ‘jointing’ each tooth or cutter is necessary so that the cutting edges all align at the same height (or along a curve, etc.).

Applies to all wood and metal cutting saws (except some specialty stuff).

The genius of Joe Cox’s design, some 75 years ago, is that you can:

- sharpen the top plate cutting edge;

- sharpen the side plate cutting edge;

- joint the chain;

- set the cutters;

all in one pass of a round file, by keeping the cutters equal length!

You have to sharpen an old fashioned crosscut saw (‘misery whip’) to really appreciate this.

Chains that have cutters at different height, and with different set, will still cut, but not as efficiently. It’s like driving a car with different pressure in each of the four tires.

Philbert