- Local time

- 1:13 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,877

- Reaction score

- 59,120

- Location

- Croatia

Yes, freehand on a bench grinder.You sharpen that?

Didn't even dress the wheel.

1/2" HSS-Co drill bit.

Do You think it'll cut?

Yes, freehand on a bench grinder.You sharpen that?

Yes. I think it’ll cut. I’m pretty darn sure it will. I need a full explanation on the how. I can sharpen one to get by. But I screw up several times.Yes, freehand on a bench grinder.

Didn't even dress the wheel.

1/2" HSS-Co drill bit.

Do You think it'll cut?

The big drills are ezy , when you need to sharpen a .063 by hand then you’re taking, but you do it for a few decades like Wilhelm and I it becomes second nature,I usually use carbide in my work, it sharpens ezy’er in my opinion, biggest issue people have is getting correct radial relief, angle, clearances,Yes. I think it’ll cut. I’m pretty darn sure it will. I need a full explanation on the how. I can sharpen one to get by. But I screw up several times.

Are You providing drinks & food if I come by to teach You "the how"?Yes. I think it’ll cut. I’m pretty darn sure it will. I need a full explanation on the how. I can sharpen one to get by. But I screw up several times.

Yeah, I have been at this game way too long, nearing full 3 decades.The big drills are ezy , when you need to sharpen a .063 by hand then you’re taking, but you do it for a few decades like Wilhelm and I it becomes second nature,I usually use carbide in my work, it sharpens ezy’er in my opinion, biggest issue people have is getting correct radial relief, angle, clearances,

I’m in my 4th decade buddy,Are You providing drinks & food if I come by to teach You "the how"?

Yeah, I have been at this game way too long, nearing full 3 decades.

But, I love grinding/sharpening drill bits.

The smallest OD I ever ground is 1.0mm and the coworker I sharpened it for made a point to come back and tell me that the bit performed very well.

To me grinding drill bits is what for some of You is grinding/filing chainsaw chains square - second nature!

I am glad for You!I’m in my 4th decade buddy,The money to good to stop ,

Absolutely! We will eat and drink like kingsAre You providing drinks & food if I come by to teach You "the how"?

Yeah, I have been at this game way too long, nearing full 3 decades.

But, I love grinding/sharpening drill bits.

The smallest OD I ever ground is 1.0mm and the coworker I sharpened it for made a point to come back and tell me that the bit performed very well.

To me grinding drill bits is what for some of You is grinding/filing chainsaw chains square - second nature!

Sorry to hear that my friend, It’s not fair, you’re a talented guy ,I am glad for You!

My $$$ is not good, never has been.

Getting worse too.

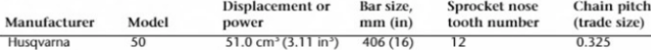

2 chains - 20LGX and 20LPX(bumper link) both straight off the roll. Both rolls made in the same year

Why are the cutters longer on LPX? Is this common? I have never had both side by side before

View attachment 449987

I don't have any pics on my phone so it will have to wait till the weekend. The good news is for the most part semi doesn't really care how it's sharpened. Just about anything will work to a degree.

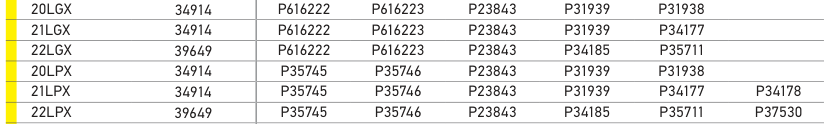

I did not not this. I always thought it was the same chain just with the humped drive link. I wonder why it's different?It's probably by design as the cutter links part numbers are different (P35745/6 vs. P616222/3). On the other hand they share tie-straps and drive links.

View attachment 450090

I did not not this. I always thought it was the same chain just with the humped drive link. I wonder why it's different?

The 70 series LGX is really hard to find here but I wonder if it's different to the LPX as well in 3/8?

So it looks to me LGX uses a longer ramped depth gauge to reduce kickback. Consequently, the depth gauge end is a little bit closer to the heel than in the LPX. This makes the top plate shorter to provide a similar space between them (gullet).Here is some more of the 20 LGX and LPX.

The overall depth gauge shape and size on the LGX compared to the gauge+ humped link on the LPX. What's the bet on how they cut compared to each other? I have mostly used the LPX in the past and my best guess is they cut exactly the same

View attachment 450294

View attachment 450295

She’ll make some chips ,All done freehand and by feel in the field using no guides or depth gauge, no expert in anymeans, just sharp enough for meView attachment 450359View attachment 450360

Some fresh oak noodles from itShe’ll make some chips ,

Dam it. I always thought the LPX was a green chain now I see it's only the BPX semi that gets the kickback rating.So it looks to me LGX uses a longer ramped depth gauge to reduce kickback. Consequently, the depth gauge end is a little bit closer to the heel than in the LPX. This makes the top plate shorter to provide a similar space between them (gullet).

Anyway, both types of chains are not of the “low kickback” type (yellow color in the US).

Arguably, the differences between the two in cutting speed may be more noticeable with boring.

Dam it. I always thought the LPX was a green chain now I see it's only the BPX semi that gets the kickback rating.

I wanted 2 of the chains as close as possible, one with the rating the other without. Now I need to find something else

Only close things I have is 23RMP (yellow?) and SP33G (green)