I have limited grinder experience so don't take my word for this. I have never been able to replicate a similar result using tilt angle on a grinder that I can get with a file.

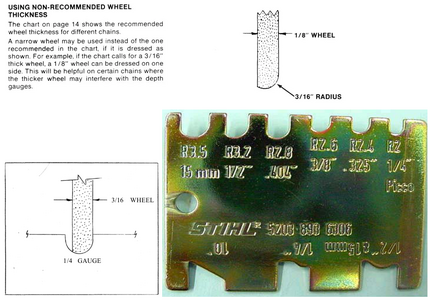

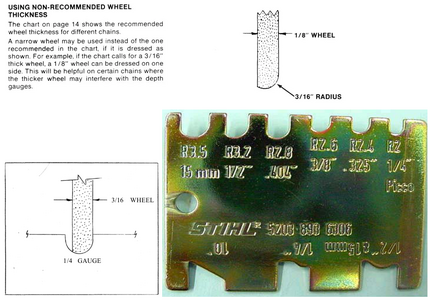

If you're looking for as much consistency as possible between sharpening with a file and a saw chain grinder, you can try to dress the wheel to match the size of the file you prefer to use. This is what Stihl recommends for their grinders.

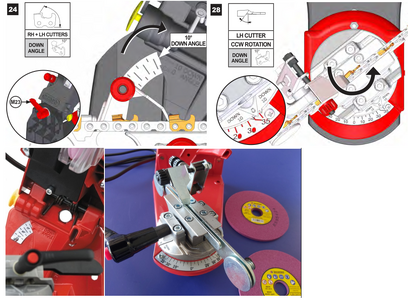

I think that by seeing these instructions and pics you will get the idea.

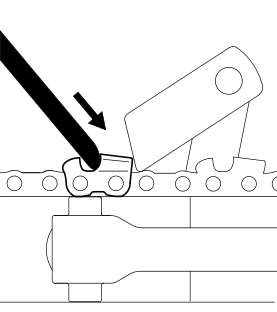

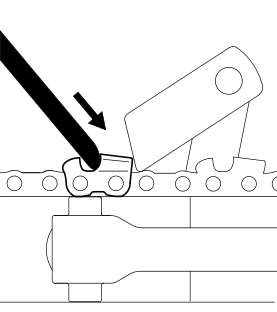

This dressed (rounded) part is in contact with the top plate during grinding.

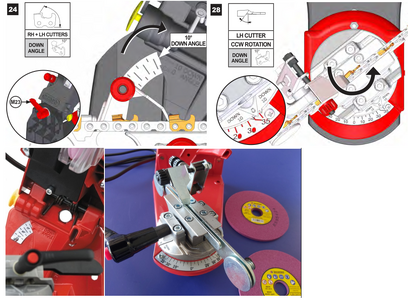

In addition, some grinders equipped with a tilting vise have auxiliary markings for a small correction of the cutting & top sharpening angle when the vise is tilted.

You really don't need a sliding vise to get good results. It is more useful for corrections related to wear of the wheel and reduction of its diameter.

511AX, although it also has a sliding vise, uses the tilt to set the "10° down angle".

Grinders (e.g., 620, Jolly Evo) that do not have a tilting vise, but do have a sliding vise, can have a scale in degrees 15-0-15 for the down angle. The USG has a scale in millimeters, and I think it may have a mistake (not the first one) in the chart when it comes to the direction of moving the vise (or we misunderstand the chart).

For me, the most important parameter I can control is how low I lower the wheel. This determines the cutting angle and side plate obtained. By lowering the wheel lower you get sharper angles and more hook. Knowing this, you can get good results even on grinders like the 310 and its cheap copies.

Very expensive automatic grinders have neither a tilting nor sliding vise.

You usually only set on them the top plate sharpening angle, the cutting angle and how deep the wheel goes down.