Ok guys, As I am new to owning a used 044 and 201T and even a 193T I have some questions for doing some maintenance to them.

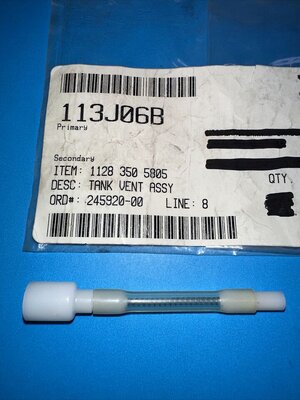

As I was pulling all my saws out of storage to look them over and fire them up, I noticed that the 201T was missing the fuel filter. The 044 I have is the Flock Air Filter style similar to my 026. So, the questions I have are these. If I get a supply of 6 or 12 Fuel Filters for the part number the 044 calls for, just how different are they than the one for the 201T and couldn't I just use the 044 ones for the 201 even if they are different part numbers? HOW critical is this? Next, I know that some 044's can use the automotive style air filter. Am I best to just get the same type OEM stock filter my saw came with, or if I'd get significantly better filtration, is it worth making the mods to the saw and switch over to the automotive style filters?

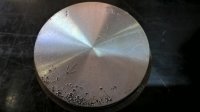

This

View attachment 460964

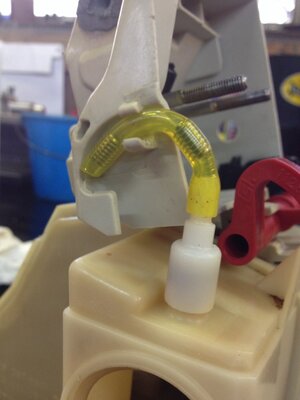

vs this

View attachment 460966

This vs the 2nd one