- Local time

- 5:51 AM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,021

- Reaction score

- 9,770

- Location

- Northern Idaho, Ehh

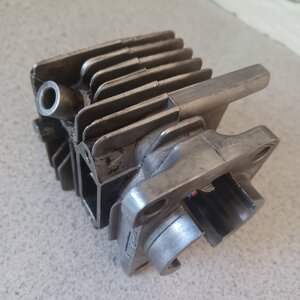

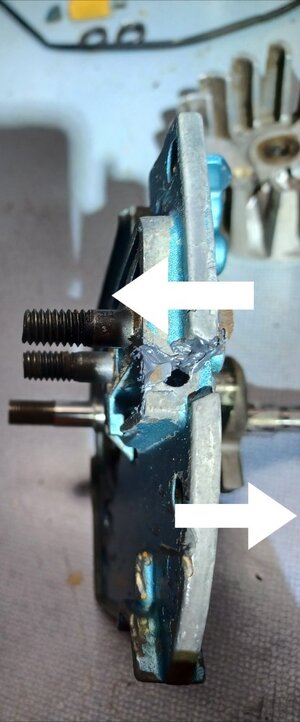

Everybody has their breaking points...I agree, McCulloch's are fun saws to work on. So far my most challenging one has been a Reed-Prentice (Craftsman) 1200B...I finally have it all apart, giving it a good clean, repairing any damage and going to have to make some new parts!I think I'm pretty good at spinning wrenches and everyone pizzes & moans about how difficult McCullough saws are to work on but honestly , if another one of these darkens my door , I'm going to pass . I'll work on a McCullough any day compared to one of these.