You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Play time?

- Thread starter Red97

- Start date

traffic903

Pinnacle OPE Member

- Local time

- 8:29 AM

- User ID

- 3911

- Joined

- Aug 28, 2017

- Messages

- 343

- Reaction score

- 1,391

- Location

- Australia

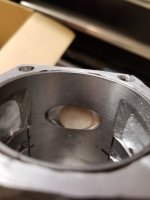

What material is it?Last try before I have to get more material.

View attachment 229605

What material is it?

Cast iron. Spin cast as a tube, just for cylinder liners

traffic903

Pinnacle OPE Member

- Local time

- 8:29 AM

- User ID

- 3911

- Joined

- Aug 28, 2017

- Messages

- 343

- Reaction score

- 1,391

- Location

- Australia

Can you run me through the pros and cons of going this route instead of replating. I guess the diy aspect is obvious and I'm really interested in doing something similar with a 3120 cylinder I have.Cast iron. Spin cast as a tube, just for cylinder liners

Can you run me through the pros and cons of going this route instead of replating. I guess the diy aspect is obvious and I'm really interested in doing something similar with a 3120 cylinder I have.

That is about the only pro... diy

May be an option for a worst case scenario jug.

But for the 200-280$ it cost to have one bored and coated with nikasil not sure if it is really worth it..

Actually if I didn't really enjoy this, just to see what I can do, I would send it out to be done.

I have 30$ and about 14 hours into this one sleeve. Now I could probably get that down to 6-8 hours but still...

traffic903

Pinnacle OPE Member

- Local time

- 8:29 AM

- User ID

- 3911

- Joined

- Aug 28, 2017

- Messages

- 343

- Reaction score

- 1,391

- Location

- Australia

And are there any issues in terms of using the cast iron? For example, can the same pistons be used? Is more bore clearance required? Is it harder on rings? Any requirement for different fuel oil mix? etc.That is about the only pro... diy

May be an option for a worst case scenario jug.

But for the 200-280$ it cost to have one bored and coated with nikasil not sure if it is really worth it..

Actually if I didn't really enjoy this, just to see what I can do, I would send it out to be done.

I have 30$ and about 14 hours into this one sleeve. Now I could probably get that down to 6-8 hours but still...

I appreciate you taking the time to answer my questions so far.

HYPERSAWS

West coast cutter

- Local time

- 1:29 PM

- User ID

- 8773

- Joined

- Feb 19, 2019

- Messages

- 1,079

- Reaction score

- 7,912

- Location

- Oregon

Is U.S chrome where you would send it to be bored and replated?That is about the only pro... diy

May be an option for a worst case scenario jug.

But for the 200-280$ it cost to have one bored and coated with nikasil not sure if it is really worth it..

Actually if I didn't really enjoy this, just to see what I can do, I would send it out to be done.

I have 30$ and about 14 hours into this one sleeve. Now I could probably get that down to 6-8 hours but still...

- Local time

- 4:29 PM

- User ID

- 297

- Joined

- Dec 28, 2015

- Messages

- 5,207

- Reaction score

- 34,317

- Location

- Central Ohio

for blind cylinders US Chrome is the best optionIs U.S chrome where you would send it to be bored and replated?

MG porting

Pinnacle OPE Member

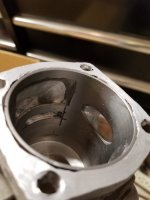

That's pretty dang impressive.45,50,52,54,56mm all in the same chassis...

View attachment 229695

And are there any issues in terms of using the cast iron? For example, can the same pistons be used? Is more bore clearance required? Is it harder on rings? Any requirement for different fuel oil mix? etc.

I appreciate you taking the time to answer my questions so far.

Don't really have all the answers...

But have 1 liner cylinder that runs, only a couple tanks use so far.

Used the same piston/caber ring

I try and hit .002 clearance on this one. Looks to be pretty close in the ring travel area, more under the intake port from the hone flairing out trying to finish by the band.

Ring life? Idk? Some of the fancy rings may actually be hard on the bore..

I use the same heavy 40:1 ish in everything.

Is U.S chrome where you would send it to be bored and replated?

That was who I called, they didnt act super interested, stating how difficult it was to do a blind cylinder. Didn't matter size etc said price is 276$ if we think we can even do it. And may be more if they have to send out to id grind. Imagine he was taking about open transfer cylinders.

It's possible to make a sleeve from 6082 t6 alu and have it nicasil plated.

Cast iron keeps the heat in the sleeve and the 6082 gives the heat further tru the cylinder.

I'm sure it is. But I know plating an open bore is at least 150$

So it is rather cost prohibitive, vs sending a jug to us chrome for bore/plate.

mgr1

Pinnacle OPE Member

- Local time

- 10:29 PM

- User ID

- 2365

- Joined

- Dec 27, 2016

- Messages

- 520

- Reaction score

- 1,207

- Location

- Belgium

I'm sure it is. But I know plating an open bore is at least 150$

So it is rather cost prohibitive, vs sending a jug to us chrome for bore/plate.

I know, i am just a jealous guy...

traffic903

Pinnacle OPE Member

- Local time

- 8:29 AM

- User ID

- 3911

- Joined

- Aug 28, 2017

- Messages

- 343

- Reaction score

- 1,391

- Location

- Australia

Thanks for that. Much appreciated.Don't really have all the answers...

But have 1 liner cylinder that runs, only a couple tanks use so far.

Used the same piston/caber ring

I try and hit .002 clearance on this one. Looks to be pretty close in the ring travel area, more under the intake port from the hone flairing out trying to finish by the band.

Ring life? Idk? Some of the fancy rings may actually be hard on the bore..

I use the same heavy 40:1 ish in everything.

That was who I called, they didnt act super interested, stating how difficult it was to do a blind cylinder. Didn't matter size etc said price is 276$ if we think we can even do it. And may be more if they have to send out to id grind. Imagine he was taking about open transfer cylinders.