Happy new year! So I’ve been messing around (I use that term very loosely) with chainsaws for most of my life. Recently I’ve had a heightened interest in diving further into them and seeing if I could improve the performance of some of my older saws. Mainly just getting them back to running around factory spec before trying any porting or anything like that.

I’m cursed with a problem that when I dive into something I go all out! Haha. I’ve already got most of the tools to work on my saws, but when I started gathering resources for porting tools, a small lathe and other more specialized items I started pumping the brakes a little and wanted to ask the advice of the builders here.

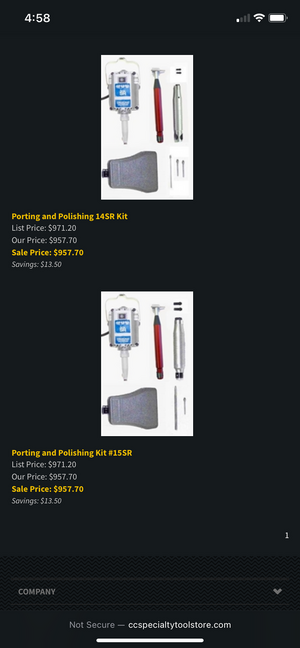

I started looking at porting tools and saw the foredom was the ticket, I didn’t want to buy a dremel or anything to “get by” because I’m a firm believer in just buying the right tool from the start, rather than possibly becoming frustrated from inferior and inadequate tools and quitting all together. Looking back at your beginning into saw building would you piece together a porting set up, or go to a company like CC Specialty and just buy one of their kits? For anyone who has bought their kit, which did you choose and why? Happy new year and have a great 2024! Thank you all!

I’m cursed with a problem that when I dive into something I go all out! Haha. I’ve already got most of the tools to work on my saws, but when I started gathering resources for porting tools, a small lathe and other more specialized items I started pumping the brakes a little and wanted to ask the advice of the builders here.

I started looking at porting tools and saw the foredom was the ticket, I didn’t want to buy a dremel or anything to “get by” because I’m a firm believer in just buying the right tool from the start, rather than possibly becoming frustrated from inferior and inadequate tools and quitting all together. Looking back at your beginning into saw building would you piece together a porting set up, or go to a company like CC Specialty and just buy one of their kits? For anyone who has bought their kit, which did you choose and why? Happy new year and have a great 2024! Thank you all!