You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Machining for port work

- Thread starter Deets066

- Start date

Deets066

AKA Deetsey

- Local time

- 8:53 AM

- User ID

- 290

- Joined

- Dec 28, 2015

- Messages

- 15,443

- Reaction score

- 73,596

- Location

- Illinois

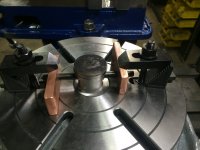

That's a possibility, but most jugs won't have enough thickness on the base. Like the 046, especially when removing .040 off the base tooI see this too, a fixture with a base plate like Randy's . Then a cage with four adjustment screws that come in from the sides and land on the side of the base. Or for even more holding power/stability two screws on each side/flat.

- Local time

- 8:53 AM

- User ID

- 441

- Joined

- Jan 8, 2016

- Messages

- 4,287

- Reaction score

- 10,976

- Location

- Farmington, CT

@Mattyo, I'd like to see how you do the case milling. Didn't you have a video at one time?

many of my vids contain milling, the vids are so boring though, most people never get there

i'll let you cheat and just watch this one...this is an ms200t

- Local time

- 8:53 AM

- User ID

- 441

- Joined

- Jan 8, 2016

- Messages

- 4,287

- Reaction score

- 10,976

- Location

- Farmington, CT

Nope

go to 11 min mark or so

go to 11 min mark or so

- Local time

- 7:53 AM

- User ID

- 4

- Joined

- Dec 3, 2015

- Messages

- 52,954

- Reaction score

- 352,753

- Location

- Banner Springs Tennessee

Where I see a mill being most useful is on a clamshell design. I raised the bearing pockets on a wildthing with a boring bar, milling table, and a drill press....

- Local time

- 8:53 AM

- User ID

- 441

- Joined

- Jan 8, 2016

- Messages

- 4,287

- Reaction score

- 10,976

- Location

- Farmington, CT

sounds like a lot of work for a wild thingy...

I like milling husky 350 riser blocks... VERY simple w/ a mill

I like milling husky 350 riser blocks... VERY simple w/ a mill

- Local time

- 7:53 AM

- User ID

- 4

- Joined

- Dec 3, 2015

- Messages

- 52,954

- Reaction score

- 352,753

- Location

- Banner Springs Tennessee

I was learning stuff Matt......cheap saws to destroy. lol

super3

Pinnacle OPE Member

- Local time

- 8:53 AM

- User ID

- 358

- Joined

- Dec 31, 2015

- Messages

- 355

- Reaction score

- 1,299

- Location

- Indiana

many of my vids contain milling, the vids are so boring though, most people never get there

i'll let you cheat and just watch this one...this is an ms200t

Why do you think +/- .001 is close enough?

- Local time

- 8:53 AM

- User ID

- 441

- Joined

- Jan 8, 2016

- Messages

- 4,287

- Reaction score

- 10,976

- Location

- Farmington, CT

good question... I dunno.... why do you think it isn't?

super3

Pinnacle OPE Member

- Local time

- 8:53 AM

- User ID

- 358

- Joined

- Dec 31, 2015

- Messages

- 355

- Reaction score

- 1,299

- Location

- Indiana

Matt,

+/- .001 from exhaust side to intake won't be a big deal.

Flywheel to clutch side is going to put side load on the piston.

Deets, I disagree with your thoughts on factory machine centers. Far more accurate than .001.

On a lathe set up you use an indicator with a lot more precision than the type in Matt's vid. .0005 graduations.

Not uncommon at all to get it dead nuts on.

+/- .001 from exhaust side to intake won't be a big deal.

Flywheel to clutch side is going to put side load on the piston.

Deets, I disagree with your thoughts on factory machine centers. Far more accurate than .001.

On a lathe set up you use an indicator with a lot more precision than the type in Matt's vid. .0005 graduations.

Not uncommon at all to get it dead nuts on.

- Local time

- 7:53 AM

- User ID

- 4

- Joined

- Dec 3, 2015

- Messages

- 52,954

- Reaction score

- 352,753

- Location

- Banner Springs Tennessee

I aim for zero run out with a .0005 indicator.

Don't always get perfect, but I always try to.

Don't always get perfect, but I always try to.

- Local time

- 8:53 AM

- User ID

- 441

- Joined

- Jan 8, 2016

- Messages

- 4,287

- Reaction score

- 10,976

- Location

- Farmington, CT

without a better way to clamp a chassis, I don't think its possible to get more than +-.001. once I have a chassis clamped, I would need to somehow articulate the jhead to compensate for the differential...and I'm not sure it really matters that much.

would be nice to have more control w/ the milling, but I don't

still... I think it just doesn't matter that much... we are talking about a side load of .001...maybe .002 at the top of the travel of the piston. you are assuming that its better than that from the factory?

would be nice to have more control w/ the milling, but I don't

still... I think it just doesn't matter that much... we are talking about a side load of .001...maybe .002 at the top of the travel of the piston. you are assuming that its better than that from the factory?

Similar threads

- Replies

- 116

- Views

- 24K