You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another chainsaw dyno...

- Thread starter Red97

- Start date

- Local time

- 4:28 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,527

- Reaction score

- 150,449

- Location

- East Jordan, MI

It has a 346 cylinder on itVery impressive.

2149 has the same cylinder as a 2150? or this one is Xtra special?

- Local time

- 4:28 AM

- User ID

- 2523

- Joined

- Jan 24, 2017

- Messages

- 4,960

- Reaction score

- 22,966

- Location

- Berkshire County, Massachusetts

That's one angry 346

- Local time

- 4:28 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,527

- Reaction score

- 150,449

- Location

- East Jordan, MI

- Local time

- 4:28 AM

- User ID

- 2523

- Joined

- Jan 24, 2017

- Messages

- 4,960

- Reaction score

- 22,966

- Location

- Berkshire County, Massachusetts

The king of cans

- Local time

- 4:28 AM

- User ID

- 2523

- Joined

- Jan 24, 2017

- Messages

- 4,960

- Reaction score

- 22,966

- Location

- Berkshire County, Massachusetts

LOUDWhats it sound like ???

- Local time

- 4:28 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,527

- Reaction score

- 150,449

- Location

- East Jordan, MI

I only ran it once like that while I was waiting for a new muffler to arrive.Whats it sound like ???

Dieselshawn

Pinnacle OPE Member

- Local time

- 4:28 AM

- User ID

- 804

- Joined

- Feb 6, 2016

- Messages

- 541

- Reaction score

- 3,001

- Location

- Southern Ontario, canada

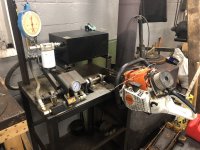

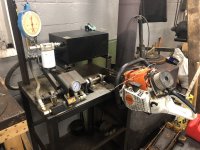

Ran a retired logging 2012 660 Magnum on my machine today.

I didn’t have the dyno at the time when I got the saw. I would’ve tested the saw before I did any work to it.

This saw was almost all in pieces in the logger’s parts box. Just the crank case with the cylinder still on.

They went to 661’s so the 660’s were not needed anymore. So I got the parts for free and assembled the saw back together with parts that were in the box. There was a hacked dual port muffler in the box too

I purchased bolts, clutch, rim, starter dogs, from a buddy that runs a small engine shop.

I noticed by spinning the flywheel, the compression feels low. Inspecting the exhaust port, I find the rings seems to be sticking. (These loggers use TC-W3 two stroke oil, shame on them)

Pulled cylinder, used the rings themselves to clean the grooves out, smeared Yamalube oil on the piston, put the cylinder back on.

Feels much better for compression.

My logging buddy pulled the rope, said saw feels like normal compression, the way it should be.

After several sheared flywheel keys, cleaning up the flywheel taper and crank taper, the flywheel finally stayed in place to run on the machine.

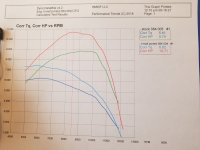

The saw made 5.2 hp at 9,000 rpms.

I didn’t have the dyno at the time when I got the saw. I would’ve tested the saw before I did any work to it.

This saw was almost all in pieces in the logger’s parts box. Just the crank case with the cylinder still on.

They went to 661’s so the 660’s were not needed anymore. So I got the parts for free and assembled the saw back together with parts that were in the box. There was a hacked dual port muffler in the box too

I purchased bolts, clutch, rim, starter dogs, from a buddy that runs a small engine shop.

I noticed by spinning the flywheel, the compression feels low. Inspecting the exhaust port, I find the rings seems to be sticking. (These loggers use TC-W3 two stroke oil, shame on them)

Pulled cylinder, used the rings themselves to clean the grooves out, smeared Yamalube oil on the piston, put the cylinder back on.

Feels much better for compression.

My logging buddy pulled the rope, said saw feels like normal compression, the way it should be.

After several sheared flywheel keys, cleaning up the flywheel taper and crank taper, the flywheel finally stayed in place to run on the machine.

The saw made 5.2 hp at 9,000 rpms.

Dieselshawn

Pinnacle OPE Member

- Local time

- 4:28 AM

- User ID

- 804

- Joined

- Feb 6, 2016

- Messages

- 541

- Reaction score

- 3,001

- Location

- Southern Ontario, canada

Saw Collector

OPE Member

You trying to start another oil thread lol.The beautiful exhaust port of my Mastermind 660. Ran many tanks of good quality oil in it. I’ve never needed to remove the muffler to clean it.

View attachment 305901

Exhaust port of the logger’s 2012 660 after several years of working every day.

ugghhh!! Terrible burning oil. Stuck rings.

View attachment 305902

Dieselshawn

Pinnacle OPE Member

- Local time

- 4:28 AM

- User ID

- 804

- Joined

- Feb 6, 2016

- Messages

- 541

- Reaction score

- 3,001

- Location

- Southern Ontario, canada

Sounds realistic. 660’s aren’t really powerhouses stock. Especially a retired logger saw with half ass compression anyway.

That’s true.

You trying to start another oil thread lol.

I think we have enough oil threads

Looks like the front cover deflector is blowing right on the clutch side case half on that 84

It is, but has a pretty decent gap.

Dieselshawn

Pinnacle OPE Member

- Local time

- 4:28 AM

- User ID

- 804

- Joined

- Feb 6, 2016

- Messages

- 541

- Reaction score

- 3,001

- Location

- Southern Ontario, canada

Last night a crushed 661 needed just a straightening of the handle, recoil from a parts saw and a quick starting test to verify it still runs.

This saw has a date scribed on it. Jan 1/2020, but ran in the bush for only a few months before a falling tree took revenge on it.

It still runs well.

5.2 hp at 9,000 rpm. Exact same power band as the old 660 that was on here prior.

So that means the 660 is still a healthy retired saw.

Even the pressure gauge read near identical psi through out the rpm range from 12,000 down to 8,000.

This saw has a date scribed on it. Jan 1/2020, but ran in the bush for only a few months before a falling tree took revenge on it.

It still runs well.

5.2 hp at 9,000 rpm. Exact same power band as the old 660 that was on here prior.

So that means the 660 is still a healthy retired saw.

Even the pressure gauge read near identical psi through out the rpm range from 12,000 down to 8,000.

Similar threads

- Replies

- 13

- Views

- 2K