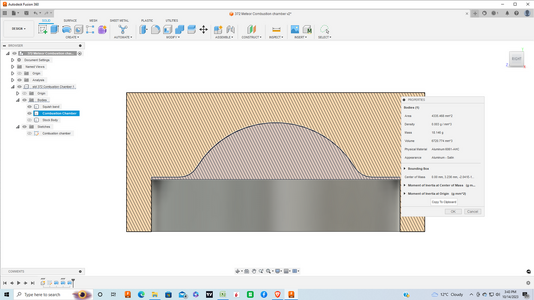

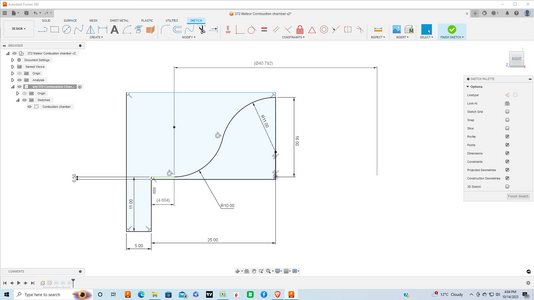

So I have a couple of examples here of chamber cross sections.

View attachment 393160

This is a near approximation of a 50mm 372 36mm stroke. The combustion chamber volume is in the box simply add the decimal point after the first digit. I don't have a cylinder here so I just made that up from my memory if its too far wrong let me know and I'll change it.

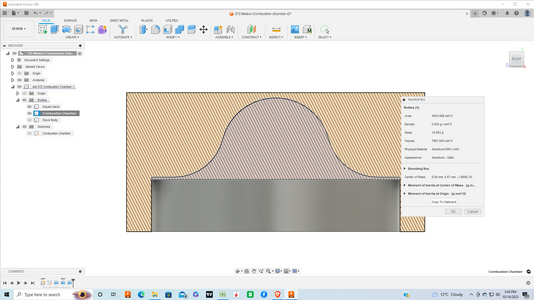

View attachment 393161

Inspired some what by the Stihl 500I a possible contender. Once again for the sake of any calculations assume a 50mm 372.

I'm interested in any thoughts of the pros and cons of each shape. More than happy to modify volumes etc if we want to drill deep into the subject.