- Local time

- 1:08 AM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

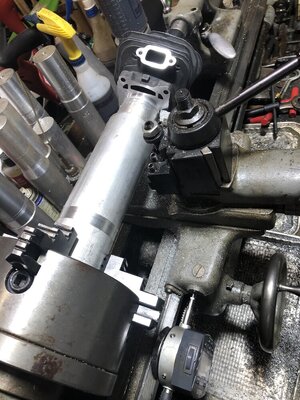

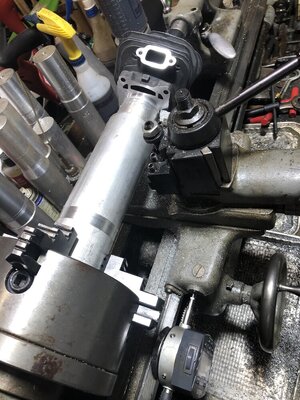

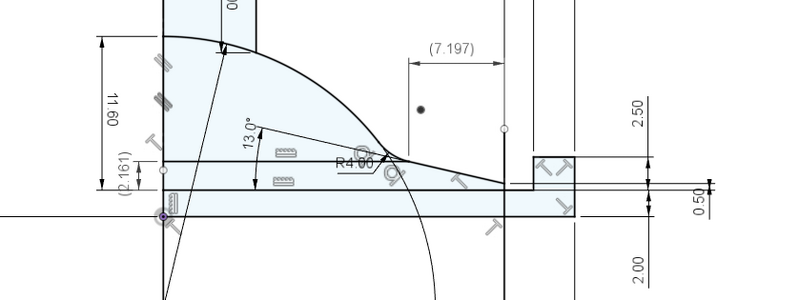

Last one I took 0.065 off the base. It gave me the opportunity to shape the transferrs nicely without having too much grinding to do. Different cuts from a flat squish because of the tapered piston crown, which is the same angle as the squish band, so much different numbers than any flat squish machining.