Terry Syd

Pinnacle OPE Member

- Local time

- 3:34 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,987

- Location

- Comboyne, NSW Australia

with that MOFO saw, I would really like to know how much is the carb and how much is the filter.

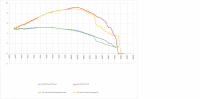

I'd bet the primary reason for the difference was the jetting of the low speed circuit. If you notice the graph, there is a big difference in power right off the bottom at 5,500. There isn't much demand for air at those low revs so a big filter (or removing the filter) shouldn't make much difference. - I also note that the power drops off earlier when it is at high revs, which is inconsistent with a high flow air filter. Perhaps as Joe said it may have been a bit rich on the high speed needle. This is where more testing on the dyno could tell what is actually going on.