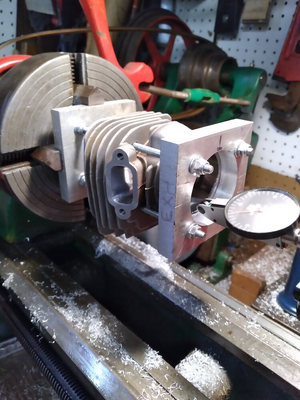

If, in theory, I can even get it to indicate in, I assure you the finish will be fodder. I'm using an hhs boring bar. There WILL be chatter. Also that 5mm all thread has flex. So also in theory, I'll be taking small nips of likely no more than 3 thou. Cause it's gonna be moving. I'm leaning on the fact that up until now, it ran on a mortar and pestil ground squish. I'll likely do that again, after. So far it looks as though I'll be incredibly lucky to get it in center and parallel within .010"

My limited 3 years experience machining, was enough to teach me that I should be scared of this setup. The only good news is that I scrapped this cylinder already by destroying the lowers.