I don't believe there are any limited coils on this chassis.

My lower transfers aren't quite as big as yours, but I can see that causing an issue on a 44.7. You have to remember that an 026 is a big bore, and a stroker on this chassis. 44mm stuff is finicky about case volume, and doesn't like any case mods at all. Idle quality and low end power suffers.

I have not built a 44.7, but everything I have ever read says ported a 44 will always outrun a 44.7.

My upper transfers are completely untouched on this particular saw, they were where I wanted them, and I built the saw a few months after a fire where we lost damn near anything, so I didn't have a 90 degree grinder at the time.

View attachment 369578

View attachment 369577

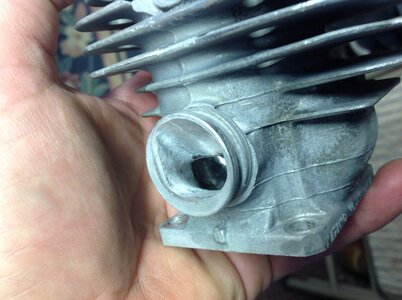

Yes, the lower ring is missing, the supporting area for the gap got in the way of my intake port.

This was a super simple build, and it just plain runs.

Hardwood, softwood, short bar, long bar, it doesn't care, just don't open up the muffler, then it falls on its face.

This is a stock carb WT194 build.