You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Saw video thread

- Thread starter Deets066

- Start date

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 1:26 PM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,796

- Location

- South Carolina

OH,TOO CLOSE! Lolnearly........

MustangMike

Mastermind Approved!

- Local time

- 1:26 PM

- User ID

- 338

- Joined

- Dec 30, 2015

- Messages

- 11,546

- Reaction score

- 36,440

- Location

- Brewster, NY

Good thing the tree did not hit you. I would recommend a shallower notch and leave enough hinge, so the saw does not get stuck and then wedge it over.

Always get back when the tree starts to fall, especially if you can see it is not a clean drop.

Your life is worth more than the saw.

Always get back when the tree starts to fall, especially if you can see it is not a clean drop.

Your life is worth more than the saw.

Timjus

Pinnacle OPE Member

- Local time

- 8:26 PM

- User ID

- 20741

- Joined

- Nov 23, 2021

- Messages

- 230

- Reaction score

- 2,016

- Location

- Finland

just miss read the lean and not securing it with wedge early enough . tree was rotten and frozen it was -15 celcius dayWhat happened there? Do something wrong, or just stuff happens sometimes?

cuinrearview

Handy dood

- Local time

- 1:26 PM

- User ID

- 9248

- Joined

- Apr 16, 2019

- Messages

- 11,568

- Reaction score

- 80,210

- Location

- Dowling, MI

Do you have the Stihl ones? The WCS look a little thinner.$16ish plus shipping.

cuinrearview

Handy dood

- Local time

- 1:26 PM

- User ID

- 9248

- Joined

- Apr 16, 2019

- Messages

- 11,568

- Reaction score

- 80,210

- Location

- Dowling, MI

Not available here last I knew. @AlfA01 got me mine.No, my local Stihl dealer is 100% full retail on everything, all the time. I don't go there, but I would try one out.

chipper1

Here For The Long Haul!

- Local time

- 1:26 PM

- User ID

- 1463

- Joined

- Jun 25, 2016

- Messages

- 6,391

- Reaction score

- 24,031

- Location

- Grand Rapids Mi

Thanks.$16ish plus shipping.

Me too.@AlfA01 got me mine.

Those can be quite aggressive, more so than the husky versions. They work well though as long as I'm not setting a chain up for boring.

cuinrearview

Handy dood

- Local time

- 1:26 PM

- User ID

- 9248

- Joined

- Apr 16, 2019

- Messages

- 11,568

- Reaction score

- 80,210

- Location

- Dowling, MI

Boring woodcutters need not applyThanks.

Me too.

Those can be quite aggressive, more so than the husky versions. They work well though as long as I'm not setting a chain up for boring.

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 1:26 PM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,796

- Location

- South Carolina

Just going through some of the Homelite super Xl-12s I've been grabbing out of scrapyards.

rogue60

Here For The Long Haul!

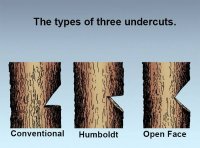

Cool vid different way of doing it he knows how to cut a nice quota butt log for milling no waste.

What's the go with the "conventional notch" in logging hardwoods I see overseas on youtubes?

In all my years I've never seen it down here not with hardwoods and logging anyway or softwoods for that matter..

Hypothetically if a truck load of quota logs ever turned up all cut with a conventional notch we would say that's not getting unloaded here take it elsewhere.

We would buy logs by the cube same as all mills here..

Working out how many cubes are in a log is by measuring the length of the log then put a girthing tape around the center of the log ( barked yeah mills don't pay for bark) then look in ya little magic book and it gives ya the cubes for that log.

The reason is as a sawmill you would lose money buying logs like that.

Say as we did cut timber for railway bridges and you needed two 10x6 x 6m and you have a perfect log for it 6m long and the right size to get them out of free of heart but thanks to a conventional face cut one side is short! That's a difference of thousands of dollars that can't be made out of that butt log.

A good cutter ya tell him the lengths you want he would give you 50-100mm over on ya lengths or close to right on if no other options never under length, even mechanical harvesting they do the same with hardwoods.

Gives you a little to clean the log up a bit as you buck the log to whatever lengths the sawmill is cutting for orders and chit.

The conventional face cut is a waste of the best butt log timber you can't put that wood back on at the mill that side of the log is SHORT a total waste.

I don't get it myself surely the mills must deducted that lost timber out paying way less for butt logs cut like that? Even still I can't get my head around the waste at the stump if it's a industry wide practice.

Don't get me wrong not saying a conventional face cut doesn't have its place just mill logs it has no purpose it's nothing more than a waste of the best butt log timber.

What's the go with the "conventional notch" in logging hardwoods I see overseas on youtubes?

In all my years I've never seen it down here not with hardwoods and logging anyway or softwoods for that matter..

Hypothetically if a truck load of quota logs ever turned up all cut with a conventional notch we would say that's not getting unloaded here take it elsewhere.

We would buy logs by the cube same as all mills here..

Working out how many cubes are in a log is by measuring the length of the log then put a girthing tape around the center of the log ( barked yeah mills don't pay for bark) then look in ya little magic book and it gives ya the cubes for that log.

The reason is as a sawmill you would lose money buying logs like that.

Say as we did cut timber for railway bridges and you needed two 10x6 x 6m and you have a perfect log for it 6m long and the right size to get them out of free of heart but thanks to a conventional face cut one side is short! That's a difference of thousands of dollars that can't be made out of that butt log.

A good cutter ya tell him the lengths you want he would give you 50-100mm over on ya lengths or close to right on if no other options never under length, even mechanical harvesting they do the same with hardwoods.

Gives you a little to clean the log up a bit as you buck the log to whatever lengths the sawmill is cutting for orders and chit.

The conventional face cut is a waste of the best butt log timber you can't put that wood back on at the mill that side of the log is SHORT a total waste.

I don't get it myself surely the mills must deducted that lost timber out paying way less for butt logs cut like that? Even still I can't get my head around the waste at the stump if it's a industry wide practice.

Don't get me wrong not saying a conventional face cut doesn't have its place just mill logs it has no purpose it's nothing more than a waste of the best butt log timber.

Last edited:

Wonkydonkey

Plastic member

- Local time

- 6:26 PM

- User ID

- 3189

- Joined

- May 14, 2017

- Messages

- 5,522

- Reaction score

- 25,875

- Location

- Sussex, UK.

$16ish plus shipping.

The stihl one is a lot cheaper,

I know you can’t get it there… you have to have friends in the right places

https://www.stihl.co.uk/STIHL-Produ...e-maintenance/267816-133798/depth-gauges.aspx

Timjus

Pinnacle OPE Member

- Local time

- 8:26 PM

- User ID

- 20741

- Joined

- Nov 23, 2021

- Messages

- 230

- Reaction score

- 2,016

- Location

- Finland

[QUOTE=" Even still I can't get my head around the waste at the stump if it's a industry wide practice.

Don't get me wrong not saying a conventional face cut doesn't have its place just mill logs it has no purpose it's nothing more than a waste of the best butt log timber.

View attachment 323332[/QUOTE]

with humbolt you leave the wood in to stump. with conventional you can cut right at ground level

Don't get me wrong not saying a conventional face cut doesn't have its place just mill logs it has no purpose it's nothing more than a waste of the best butt log timber.

View attachment 323332[/QUOTE]

with humbolt you leave the wood in to stump. with conventional you can cut right at ground level