- Local time

- 5:20 AM

- User ID

- 232

- Joined

- Dec 24, 2015

- Messages

- 9,755

- Reaction score

- 67,099

- Location

- Coastal Oregon

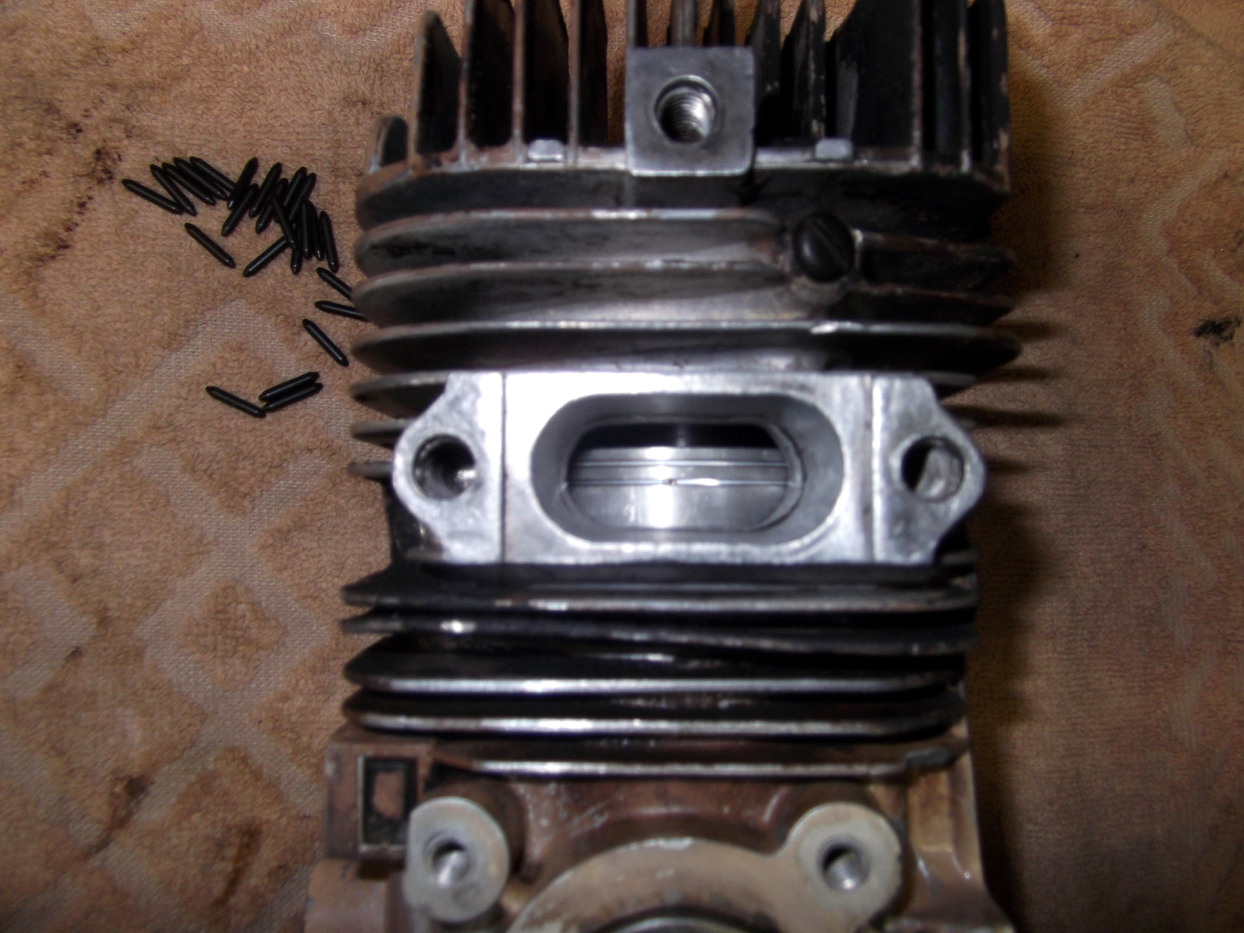

This old 795 piston had seen better days. I was from a rebuild I did for a local guy years ago. Sometimes the blind bore needle cage

comes out smoothly and sometimes the end cap just breaks off. Either way, then you can pull the pin. When they have this much

wear and tear, you don't want to try to save the needle bearings and cages anyway.

Extraction complete. In this picture, I'm showing the difference between the 795 and 797 wrist pins and connecting rods. The 797

rod is about a 1/4" longer than the 795, but the 795 wrist pin is longer. The 795 wrist pin is also a lot thicker and heavier.

comes out smoothly and sometimes the end cap just breaks off. Either way, then you can pull the pin. When they have this much

wear and tear, you don't want to try to save the needle bearings and cages anyway.

Extraction complete. In this picture, I'm showing the difference between the 795 and 797 wrist pins and connecting rods. The 797

rod is about a 1/4" longer than the 795, but the 795 wrist pin is longer. The 795 wrist pin is also a lot thicker and heavier.