The only real issue with AT, is that it becomes a distraction. A saw arrives scored/wiped. Had it been a non-AT saw, proper diagnostics as to why it failed would likely have been employed. But we got all hung up on auto-tune and those silly print outs and forgot we were fixing a chainsaw. Basic troubleshooting never really took place, the saw was rebuilt, and no doubt failed due the original fault not being found. Simple things like water in the fuel get overlooked because of the suspicion that AT is the likely cause of any problem. AT should be looked at LAST, not first.

There was a bearing pocket alignment issue on some of the early 372XT's, but that is the only example I'm aware of.

I was lucky enough to be "connected", and had the advantage of being able to talk to product specialists in Sweden on a lot of stuff. They did extensive testing that showed plastic cages lasted longer, over a wider temperature range than steel cages. These choices are made at the engineering level, not the bean counter level. There's a lot of "I'm smarter than those guys" chatter on the internet. Walt loves to debate the plastic vs steel cage thing. For hours.

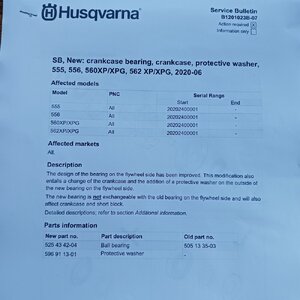

Staying up to date on service bulletins is important. And it's nothing new. You'd all be quite entertained reading service bulletins going back into the 2xx series saws and finding the good ole days were not as perfect as we like to remember. There is a ton of information to be accessed, vs the inclination to play Sherlock Holmes that many suffer from. There times when you're experiencing the mystery before the solution has been found, and that can be frustrating.

Many bearing issues have historically been supplier related. About a year ago, the 550m2 bearing supplier was changed from SKF to HQW for improved durability. The seals involved do not interchange between the 2, just as an example of the need to stay on top of things. Similarly, the incorrectly fitted seals on some bearings was a supplier issue, that was able to be corrected by same. Any change is accompanied by the relevant serial number range. Such info is listed on both the service bulletis and IPL updates. If you don't know when changes took place, you can't even order the right parts.

I understand most dealers don't deep dive into this info. Particularly where saws are sold in compact tractor and motorsports shops. The result is that many of you guys know far more about saws than those dealers do. But be careful drawing conclusions from small and inadequate sample size. I saw a LOT of saws pass over my bench over the years. Thousands. A failure is always more newsworthy than a saw that has no issues. So, when something is amiss, how much of a problem do I see? Even within an identified serial number range, all saws will not experience the potential problem. The concern that every saw is going to blow up is unfounded.

Worst thing for the PTO bearing is a too tight chain. Some customers were notorious for this, and would destroy the bottom end of any saw. Other customers never had problems. Some take care of their tools, some don't.

How's that for a rant, Randy? That'll teach ya to tag me in a post.