HumBurner

Pinnacle OPE Member

- Local time

- 11:33 PM

- User ID

- 23235

- Joined

- Apr 19, 2022

- Messages

- 1,188

- Reaction score

- 3,662

- Location

- Humboldt

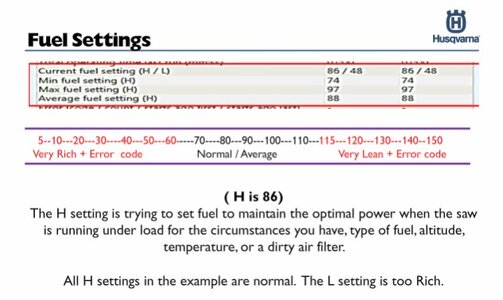

Even though it's an electronic controlled carb it can still suffer from the typical fuel delivery problems that you probably won't be clued into until it's too late. Clogged fuel filters or screens, and stiff diaphragms will cause them to lean out up top enough that the AT can no longer compensate for it.

Why has Husqy not initiated a "reset then kill" command when the numbers start to lean out like this?

It attempts to reset/retune, then if the new numbers don't stick , the saw will not run until flashed/fixed?

Edit: autocorrect done fudged that post all up!

Last edited: