Bob95065

Super OPE Member

- Local time

- 3:16 AM

- User ID

- 2097

- Joined

- Nov 7, 2016

- Messages

- 185

- Reaction score

- 398

- Location

- Felton, CA

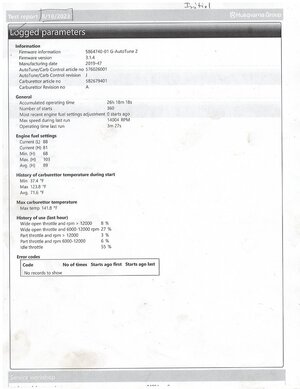

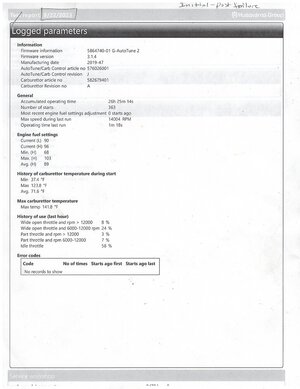

I have a Husqvarna that I got not running in pieces. The piston had light scoring but the cylinder was clean. I got no other information with this saw like how this happened, how it ran, any history of problems, etc. I put a Meteor piston and a Caber ring in it and started the saw to be sure it ran. Once it started and idled a minute I immediately shut it down and took it to the dealer to get the data off the carburetor processor. They tested the fuel valve, temp sensor and throttle sensor and it passed. Then they flashed the saw and got the following information from it:

I wanted the tech to update the firmware but he talked me out of it. He said the numbers looked good and he recommended I leave it alone. In hindsight I should have insisted but I figured he knew more about these saws than I do since this was my first experience with Autotune.

Saturday I brought the 562 along with my antique roadshow saws to cut up some firewood. I ran a 20" bar on the saw for two reasons: first, I had a bar and a sharp 20" chain and second I didn't want to load the engine too much until the rings seated. It ran great and I heard a warble in the cut. when I went to idle it stopped. I started it again and cut a short time and it stopped. I went to start it and I got a sinking feeling due to low compression. I used my older saws the rest of the day.

I couldn't wait to get home to pull the muffler When I did I saw a scored piston. I went back to the hardware store/dealer for a couple of rubber stoppers for the intake so I could do a compression test. I ran into the tech who flashed my saw and an older tech that worked there. I told them what happened and we started going through causes for the failure. The older tech asked me what bar I was running and what I was cutting. I told him a 20" bar and logs up to about 16" or 18". He said that was a full bar cut that overloaded the saw before breaking it in. That didn't sound right to me because that saw can take a lot more bar than 20". Also they said running it wide open out of the cut would overheat it too. I thought that's how the computer tuned it. We agreed that I would bring the saw back after work today. I went home and did a vacuum test and the case held vacuum. I got the cylinder off and took the piston out. It's fried. What is more disappointing is the coating in the cylinder was compromised and it's not a paperweight.

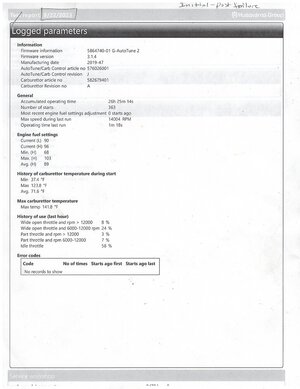

Today we pulled the data off the saw and the tech said that it leaned itself out. This is what the printout said:

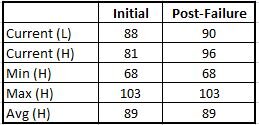

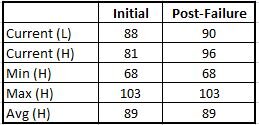

So comparing the two this is what I have:

In talking with him it isn't clear to me what these numbers mean. Does anyone have insight to what the saw did? Does anyone know what these numbers mean and what the scale is Husqvarna is using? I see that L went up 2 counts and H 15 counts. I don't know what this means.

If you look at the two scans above you will see that I ran that saw 7 minutes.

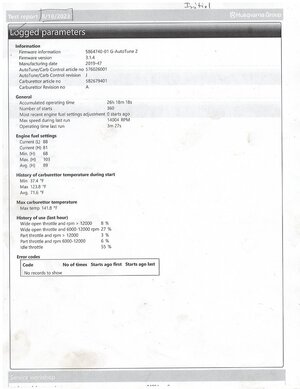

I had them update the firmware like I should have done the first time I went up there. This is what is shows:

So the firmware version went from 3.1.4 to 3.2.4. He said that was a big jump and should fix the problem. I noted that the numbers hadn't changed and he said they wouldn't until I started the saw. The thing is I feel like I am rolling dice here. I need to hunt down a new jug and slug and when I do I won't know if that computer will trash them in 7 minutes again or not. I think the safest thing to do would be to fix the saw, start it and let it tune then shut it down and take it back to see the tuning numbers on the printout. I read that the Duke's P/C sets are good quality, does any one have experience with them?

There's something to be said about two mixture screws and an idle adjustment screw. I like the spark advance but not the fuel mixture in Autotune.

Any help or comments are appreciated.

Bob

I wanted the tech to update the firmware but he talked me out of it. He said the numbers looked good and he recommended I leave it alone. In hindsight I should have insisted but I figured he knew more about these saws than I do since this was my first experience with Autotune.

Saturday I brought the 562 along with my antique roadshow saws to cut up some firewood. I ran a 20" bar on the saw for two reasons: first, I had a bar and a sharp 20" chain and second I didn't want to load the engine too much until the rings seated. It ran great and I heard a warble in the cut. when I went to idle it stopped. I started it again and cut a short time and it stopped. I went to start it and I got a sinking feeling due to low compression. I used my older saws the rest of the day.

I couldn't wait to get home to pull the muffler When I did I saw a scored piston. I went back to the hardware store/dealer for a couple of rubber stoppers for the intake so I could do a compression test. I ran into the tech who flashed my saw and an older tech that worked there. I told them what happened and we started going through causes for the failure. The older tech asked me what bar I was running and what I was cutting. I told him a 20" bar and logs up to about 16" or 18". He said that was a full bar cut that overloaded the saw before breaking it in. That didn't sound right to me because that saw can take a lot more bar than 20". Also they said running it wide open out of the cut would overheat it too. I thought that's how the computer tuned it. We agreed that I would bring the saw back after work today. I went home and did a vacuum test and the case held vacuum. I got the cylinder off and took the piston out. It's fried. What is more disappointing is the coating in the cylinder was compromised and it's not a paperweight.

Today we pulled the data off the saw and the tech said that it leaned itself out. This is what the printout said:

So comparing the two this is what I have:

In talking with him it isn't clear to me what these numbers mean. Does anyone have insight to what the saw did? Does anyone know what these numbers mean and what the scale is Husqvarna is using? I see that L went up 2 counts and H 15 counts. I don't know what this means.

If you look at the two scans above you will see that I ran that saw 7 minutes.

I had them update the firmware like I should have done the first time I went up there. This is what is shows:

So the firmware version went from 3.1.4 to 3.2.4. He said that was a big jump and should fix the problem. I noted that the numbers hadn't changed and he said they wouldn't until I started the saw. The thing is I feel like I am rolling dice here. I need to hunt down a new jug and slug and when I do I won't know if that computer will trash them in 7 minutes again or not. I think the safest thing to do would be to fix the saw, start it and let it tune then shut it down and take it back to see the tuning numbers on the printout. I read that the Duke's P/C sets are good quality, does any one have experience with them?

There's something to be said about two mixture screws and an idle adjustment screw. I like the spark advance but not the fuel mixture in Autotune.

Any help or comments are appreciated.

Bob