DrewUth

Too weird to live, too rare to die.

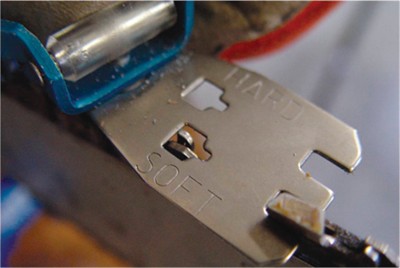

I am by no means skilled when sharpening my own chains, but I use the guides that clip onto files, touch them up with every tank of fuel and only mess with the rakers every 5-6 filings, using a raker gauge. I take care to keep the chains clean and sharp, and pay close attention to the angles on the cutters, so that they are my friend and not my foe when cutting haha.

Recently, I have been banging my head against the wall with a few loops of 3/8" chain that cut crooked. I know that cutter length is not the determining factor here, but instead this is due to the rakers...at least thats what I have read? I can say that my cutters are not all the same size...but I file the rakers with care to keep them as close to the same as possible. The bar on the saw is not the issue either, as I put on a loop of brand new chain the other day and it cut straight (the oregon chain with the "bent over" rakers...I had hung it on the wall as it doesnt really cut as aggressive as I want it to). I want the chains to cut on the aggressive side, but I need them to cut straight...all my firewood is crooked and its embarrassing!

Ideas on how to correct these loops? What am I mucking up? I have 3-4 loops that have plenty of cutter life left, but I am ready to replace them out of frustration...

EDIT- I am using oregon LPX chain, I realize I left that out.

Recently, I have been banging my head against the wall with a few loops of 3/8" chain that cut crooked. I know that cutter length is not the determining factor here, but instead this is due to the rakers...at least thats what I have read? I can say that my cutters are not all the same size...but I file the rakers with care to keep them as close to the same as possible. The bar on the saw is not the issue either, as I put on a loop of brand new chain the other day and it cut straight (the oregon chain with the "bent over" rakers...I had hung it on the wall as it doesnt really cut as aggressive as I want it to). I want the chains to cut on the aggressive side, but I need them to cut straight...all my firewood is crooked and its embarrassing!

Ideas on how to correct these loops? What am I mucking up? I have 3-4 loops that have plenty of cutter life left, but I am ready to replace them out of frustration...

EDIT- I am using oregon LPX chain, I realize I left that out.