I know that cutter length is not the determining factor here, but instead this is due to the rakers...at least thats what I have read?

As noted, there are a few things that can affect this. In general, you want

all of the cutters on a loop the

same: same length, same angles (all), same depth gauge setting, etc.

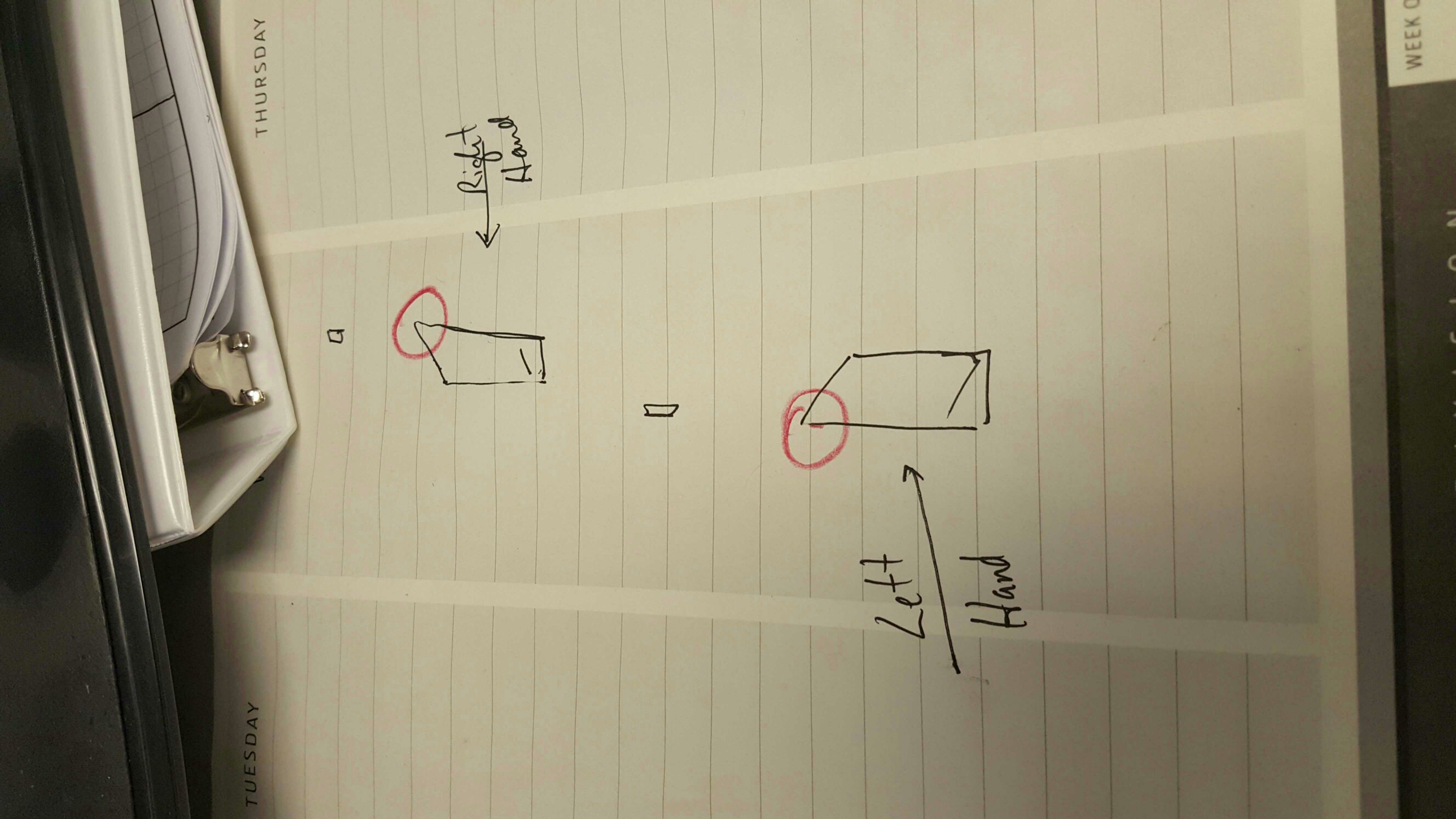

Ok, so related question- when calling the cutters left or right, are you going by the corner of the cutter or the open side?

With the chain mounted in the chainsaw, the cutters on your Left side, as you are holding the saw in the cutting position, are the 'Left' cutters.

Its a quick little tip on how I check cutter eveness.

Simple and effective. Will also show if your top plate angles are different between the sides (common on hand filed chain).

There are lots of ways to sharpen a chain. Whatever you use, focus on the

results, not the

method. In other words, don't just count the number of strokes that you take on each tooth, but examine them when done to see if they are the same length and same angles. Often, people are stronger on one side than the other, so they either need to adjust their effort on one side, or compensate with the number of file strokes.

Examine each cutter with good light, and maybe some type of magnifier: are you getting clean metal on both the top and side cutting edges? Can you see light reflecting off of the finished edge (it should not on a sharp edge)?

Take your time and get each cutter to look the way you want it. Worry about speed later.

Philbert