You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

can we have basic porting term thread?

- Thread starter cobey

- Start date

Termitebuffet

Home of the corn can muffler .....

- Local time

- 4:21 AM

- User ID

- 383

- Joined

- Jan 2, 2016

- Messages

- 2,627

- Reaction score

- 11,961

- Location

- Midgetville Norf Kacolacky

I hope I never ,ever have to work another night shiftI'm sure. I've not worked near as much nights as I used to.

Zoo City Sawz

B

Backyard Lumberjack

Guest

The putting back is kinda hard ....lol [emoji200]

Zoo City Sawz

for those interested, what I learned today, is enthusiasm is one thing... desire and motivation quite another... but before you get further than mere casting clean up... lay out your port shape modifications with some medium as painter's blue tape. then you wont go wrong... just know... the ring gap rides on the thin side, not over there on the exhaust side of cyl where it is wide...

I had an apprehensive moment today, but alas!!... room to spare, however as I mentioned over in finger porting thread... not 2 rooms! I really had thought: well, oh damn! me and my wider is better... first saw porting, first ruined cylinder!!!

Great thread!

dall

Mastermind Approved!

- Local time

- 4:21 AM

- User ID

- 795

- Joined

- Feb 5, 2016

- Messages

- 48,770

- Reaction score

- 201,576

- Location

- grafton wv

i use to love nights and would be up in the morning and get called to go into work on a emergency outage for that night and be there till 7 or later the next morning it makes a old man out of you

- Local time

- 4:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,475

- Reaction score

- 150,098

- Location

- East Jordan, MI

Yea the whole "ring end" thing without an assortment of small squares and measuring tools is voodoo. It takes a good eye to figure out where they're at on the cylinder wall. Unless they line up with the skirt. On a used jug you can usually see where the skirt rodefor those interested, what I learned today, is enthusiasm is one thing... desire and motivation quite another... but before you get further than mere casting clean up... lay out your port shape modifications with some medium as painter's blue tape. then you wont go wrong... just know... the ring gap rides on the thin side, not over there on the exhaust side of cyl where it is wide...

I had an apprehensive moment today, but alas!!... room to spare, however as I mentioned over in finger porting thread... not 2 rooms! I really had thought: well, oh damn! me and my wider is better... first saw porting, first ruined cylinder!!!lol... then thot, oh ring gap rides on wide side... surely... but then I mocked up the piston and rings spaced to ring pins.... eeek!

close, but no cigar! room to spare [as BL wiped his forehead]... well, I got that lesson down pat now... LOL

B

Backyard Lumberjack

Guest

I lay out ring ends if it's something I've not done 5 or more of. Thin marker and a set of calipers is what I use to make vertical lines.

I pulled it off thinking: conservative, know your port, the mod... and its mechanical effect on other related items... the air flow is 2ndary, if u miss your mark! if in doubt

here I will show you all on my 044 porting project... sure was a fun afternoon... sunny, windy... C&W playing an me sitting at my chain saw porting bench... for first time. main thots: really do need to move this inside... lol... ie, warmer

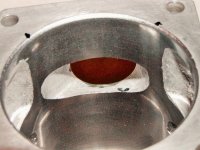

lookie here... almost got my tail end bit... its kinda ghostly... but u can see the ring line... up down... burnished in pattern... trust me, that port is as wide as its gunna get!!! lol... on the intake side, L. but interestingly enough, I did not go overboard, loose my place... or fall asleep with the porting tool spinning at 35,000 rpms... I was just pushing the OE casting a bit... i bet the pattern shifted as a mold. ok to run, but not to modify. really almost lost the cyl... but the creed of conservatism was my guide and battle cry! actually, I was just lucky!!!

close but no cigar 044 ported port:

Miller Mod Saws

Chainsaw Masseuse

- Local time

- 3:21 AM

- User ID

- 317

- Joined

- Dec 29, 2015

- Messages

- 2,069

- Reaction score

- 9,010

- Location

- Ravenwood,MO

I got this whole book if ya want to read it. Lol.

metallic

Well-Known OPE Member

- Local time

- 4:21 AM

- User ID

- 505

- Joined

- Jan 11, 2016

- Messages

- 51

- Reaction score

- 88

- Location

- Northborough, MA

I pulled it off thinking: conservative, know your port, the mod... and its mechanical effect on other related items... the air flow is 2ndary, if u miss your mark! if in doubt

here I will show you all on my 044 porting project... sure was a fun afternoon... sunny, windy... C&W playing an me sitting at my chain saw porting bench... for first time. main thots: really do need to move this inside... lol... ie, warmer

lookie here... almost got my tail end bit... its kinda ghostly... but u can see the ring line... up down... burnished in pattern... trust me, that port is as wide as its gunna get!!! lol... on the intake side, L. time to make it ring sliding happy....and some hand filing, too...

close but no cigar 044 ported port:

View attachment 9863

What's that horseshoe shaped thingy on the roof of your intake? Maybe just a casting flaw you can fill in with epoxy?

B

Backyard Lumberjack

Guest

Yea the whole "ring end" thing without an assortment of small squares and measuring tools is voodoo. It takes a good eye to figure out where they're at on the cylinder wall. Unless they line up with the skirt. On a used jug you can usually see where the skirt rode

ha! right on! voodoo, good eye... some tools, or just plain good ol luck! I learnt my lesson!!! lol.....

- Local time

- 4:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,475

- Reaction score

- 150,098

- Location

- East Jordan, MI

Pretty much all you need to be concerned about there is possibility of the piston skirt catching on the bottom of that port. I'd put a good bevel on it for sure. Rings don't travel that far down. That's a skirt wear lineI pulled it off thinking: conservative, know your port, the mod... and its mechanical effect on other related items... the air flow is 2ndary, if u miss your mark! if in doubt

here I will show you all on my 044 porting project... sure was a fun afternoon... sunny, windy... C&W playing an me sitting at my chain saw porting bench... for first time. main thots: really do need to move this inside... lol... ie, warmer

lookie here... almost got my tail end bit... its kinda ghostly... but u can see the ring line... up down... burnished in pattern... trust me, that port is as wide as its gunna get!!! lol... on the intake side, L. time to make it ring sliding happy....and some hand filing, too...

close but no cigar 044 ported port:

View attachment 9863

- Local time

- 4:21 AM

- User ID

- 360

- Joined

- Dec 31, 2015

- Messages

- 23,475

- Reaction score

- 150,098

- Location

- East Jordan, MI

Hmm. I bet it does. I just did a KS 10mm and after taking .050 off the base, I could see the bottom of the ring at bdcDoes a ring drop in the intake on a 044?