That’s what I call it also, the cranks are made up of a number of two different forgings, a “semi built” crankshaft, basically they are made of multiples of the same two parts, crank web and pin as one piece, and main crankpin as the other, they just add more to make the appropriate cylinder count, 4 through 14 cylinders.

The crank webs machine bored main journal holes are interference fit over the main crankpins with no positive locking mechanism to avoid stress raisers.

Here is photo from online of a marine slow speed two stroke crank.

Note no bob/counterweights, and the toothed gearwheel at the far end of the picture, that is the flywheel, relativity speaking they are tiny.

Same online photo source showing flywheel, again relatively small compared to smaller engines, it's main purposes is simply being a gearwheel to allow turning of the engine for maintenance and checking for unwanted fluid ingress into the cylinders before starting, it does not play much part storing energy or stabilising rpm, not used for starting either, that is achieved by timed 'start air' direct into the cylinders.

Link to photo source

http://www.marinediesels.info/2_stroke_engine_parts/Other_info/semi_built_crankshaft.htm

I spent four years operating, maintaining and fault finding Man B&W 6S70-MC engines, around 23000HP @ 91rpm, 700mm piston, 2680mm stroke, don't have many photo's at hand, but here are some of prepping a spare piston before a change out.

Lowering into maintenance position.

View attachment 259496

View attachment 259501

Prepping for new piston crown.

View attachment 259489

New crown and ring pack fitted, yours truly in place for scale.

View attachment 259479

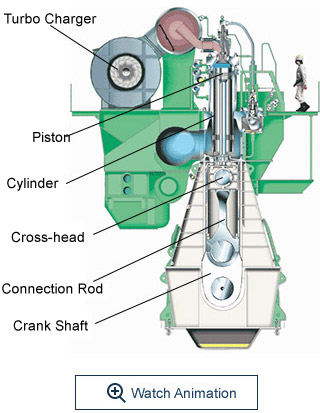

If something isn't adding up, these are a crosshead engine.