As much as anything it is the shape of the torque curve that dictates a saws

manners, not absolute numbers, and having a flat torque curve also has a drawback for a chainsaw.

Warning, Opinions inbound.

Flat torque curves give you high power, as they better maintain torque to higher rpms, but the flatter the torque curve the less of a torque boost there is to help maintain RPM when extra load is applied, hitting a knot, bar pinch, shifting extra force onto the bar, etc, effects that can be more pronounced with a longer bar.

A torque curve that drops off more substantially from peak torque to peak horsepower will better self regulate speed than a flat torque curve with minimal user input.

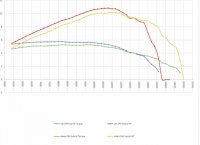

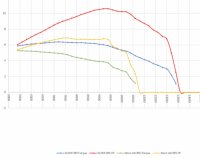

I would use a stock 395 vs 660 chart of the same HP to describe my thoughts, but didn’t see one.

The stock 395 vs SCARR 395 illustrates it well enough though, and I mean NO negativity to any saw, it’s just what happens when you perform these kind of mods.

I don't know if I have ever issued a Best Answer before, but your post deserved it and stated what I was thinking but not properly expressing.

Hp will increase cut speed, but big low end torque will inspire confidence in your saw. I really like using my Asain 660 for ripping large Oak and hard Maple rounds. I can lean on it, and it just does not quit. (Plus, it cuts faster that my other660s, seems to have more RPMs).

As you can see the ported 395 has a nice flat torque curve leading up to peak power, the stock saw dropping off more rapidly.

The ported saw has more torque everywhere, so it will of course pull the chain harder at all times, it looks like a great machine.

But let’s consider a scenario, both saws cutting at 9400rpm when a very slight bar pinch occurs, More load is placed on the chain, more torque is needed at the sprocket, the chain slows down.

Now let’s say the lightly pinched chain requires 0.2ftlb more torque at the sprocket to match the new load, simply trace the torque chart from the before pinch rpm (9400rpm), add the (load) torque increase that occurred (.2ftlb) and find the new rpm that results, as long as the saw can produce the needed torque figure anyway, and we are talking no adjusting bar/cut pressure, just letting the saw take care of itself.

Stock saw, 3.8ftlb @ 9400rpm to 4.0ftlb, rpm drops to 8750.

Ported saw 6.0ftlb @ 9400rpm to 6.2ftlb, rpm drops to 7200.

While the ported saw will drop more RPM it will still be outcutting the stock saw as it still maintains a power and torque advantage

but will some perceive the stock saw to have more torque?due to how easily it deals with deals with load increases, not dropping many rpm.

When operating past peak torque, like we do with a chainsaw flat torque curves do not provide as large a torque reserve to maintain rpm for load increases.

And I imagine the Dyno will show older larger saws that get dyno’d, the ones that love getting dogged in and are described as unstoppable will have far from flat torque curves, that their unstoppable nature is that they have a large torque reserve/increase to give as RPMs are pulled down..

Machining steel, you have to stay within the thermal limits of your cutting tools, an issue we don’t have.