You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another chainsaw dyno...

- Thread starter Red97

- Start date

Sawrain

Pinnacle OPE Member

- Local time

- 7:31 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

Another (cynical) reason that particular chainsaws might not compare as expected on the Dyno is that some saws have active propaganda machines pushing the agenda, it’s not here, but in some circles you would be forgiven for thinking it is a statement of fact that a 395xp is twice the power of a ms660.

Don’t mean to make it Husky vs Stihl but those two saws do naturally divide more than most.

Don’t mean to make it Husky vs Stihl but those two saws do naturally divide more than most.

Bigmac

Mastermind Approved!

- Local time

- 1:31 PM

- User ID

- 5937

- Joined

- Apr 19, 2018

- Messages

- 5,769

- Reaction score

- 40,640

- Location

- Oregon

That

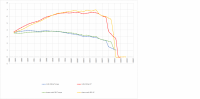

That’s kind of the point, it makes 5.4 pounds at the bottom end, and only 4 lbs at cutting rpm, either the power down low is relivent or it’s not. That is my question. If power is power then they should have the same capabilities? It can’t be rotating mass alone that lets a 395 run a long bar or lack of hp Can it?Stock 395 has about 5.4 ftlb peak.

Only a couple of the bigger 70cc saws have made more tq than a stock 395. And those were 79cc ish themselves. 5.5 ftlb

Couple of the 60's have more hp, but tq is in the 4ftlb range.

I wonder on these "torque" saws if it's not an abundance of tq we feel, but a lack of hp?

No real hp to wind out the top?

Sawrain

Pinnacle OPE Member

- Local time

- 7:31 AM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

Power is power.

Power down low (Torque) is relevant in making the saw easier to use, more forgiving in the cut, less likely to stall out and maybe you would shift power down a bit for a long bar saw so it doesn’t have to scream 12k rpm for super long hard cuts.

Rotating mass isn’t what makes the 395 an easy saw to use, it’s the torque curve, chainsaws don’t really have that much stored energy in the rotating assembly anyway, and what is there disappears pretty quick when you hit a tight spot in the cut, and once the rotating assembly gives up its energy in an rpm drop, it is an engines real torque you are relying on to keep things chugging.

Another thing with rotating mass, if your rpm is stable in a cut, then in terms of power/torque it is 100% out of the equation, flywheel/crank etc can only absorb or release energy when it’s rpm changes and going on, if you enter a cut at 10k and leave at 10k, in terms of outright performance (not usability), it just can’t influence power, because it has the same stored energy before and after, no net influence to power.

I guess the other thing is 10hp 044 sized saws aren’t normal, so less real world experience with long bars.

From Huskyboys post, there might be different chain sharpening techniques needed For high rpm long bar saws?

Power down low (Torque) is relevant in making the saw easier to use, more forgiving in the cut, less likely to stall out and maybe you would shift power down a bit for a long bar saw so it doesn’t have to scream 12k rpm for super long hard cuts.

Rotating mass isn’t what makes the 395 an easy saw to use, it’s the torque curve, chainsaws don’t really have that much stored energy in the rotating assembly anyway, and what is there disappears pretty quick when you hit a tight spot in the cut, and once the rotating assembly gives up its energy in an rpm drop, it is an engines real torque you are relying on to keep things chugging.

Another thing with rotating mass, if your rpm is stable in a cut, then in terms of power/torque it is 100% out of the equation, flywheel/crank etc can only absorb or release energy when it’s rpm changes and going on, if you enter a cut at 10k and leave at 10k, in terms of outright performance (not usability), it just can’t influence power, because it has the same stored energy before and after, no net influence to power.

I guess the other thing is 10hp 044 sized saws aren’t normal, so less real world experience with long bars.

From Huskyboys post, there might be different chain sharpening techniques needed For high rpm long bar saws?

Last edited:

Billy Currie

Pinnacle OPE Member

- Local time

- 4:31 PM

- User ID

- 7398

- Joined

- Sep 21, 2018

- Messages

- 507

- Reaction score

- 1,940

- Location

- Asheboro, NC

It would be cool to go from Dyno right into wood. Compare like saws. Same bar, chain, rim and wood. Compare the dyno results to real life wood cutting results.

This!

Cobby08

I’m a face down ass up guy

- Local time

- 4:31 PM

- User ID

- 302

- Joined

- Dec 28, 2015

- Messages

- 1,051

- Reaction score

- 4,169

- Location

- Central New Yawk...

Jiiiiinkkkeeeessss... next your going to be asking for heated leather seats with a ball fondling feature for sawing.It would be cool to go from Dyno right into wood. Compare like saws. Same bar, chain, rim and wood. Compare the dyno results to real life wood cutting results.

Jiiiiinkkkeeeessss... next your going to be asking for heated leather seats with a ball fondling feature for sawing.

Pics?

Of said gadget?

- Local time

- 10:31 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,178

- Location

- Croatia

. . . my saw is the strongest . . .

No, it's not - see the dyno graph!

The dyno is not telling the whole story . . .

The "feel of pants" is different for every individual.

The dyno graph is the same for all!

No, it's not - see the dyno graph!

The dyno is not telling the whole story . . .

The "feel of pants" is different for every individual.

The dyno graph is the same for all!

XP_Slinger

They’re Just Saws

- Local time

- 4:31 PM

- User ID

- 845

- Joined

- Feb 9, 2016

- Messages

- 6,089

- Reaction score

- 27,567

- Location

- Central NY

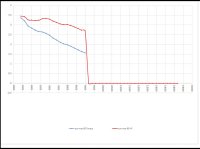

Very good example of what we feel in “torquey” saw. Dog it hard and rpm drops into higher torque range. Not as easy to see on most other graphs with very flat torque curves as you pointed out.Here is a good example of what I think we feel.

I know this saw was tuned around 10k

View attachment 254111

Pro mac 60.

Prolly hold 7-k in the wood and feels stronger the more you lean on it.

Most of the modern saws don't have as extreme torque curve rise..

- Local time

- 4:31 PM

- User ID

- 325

- Joined

- Dec 30, 2015

- Messages

- 5,096

- Reaction score

- 25,384

- Location

- Centre County

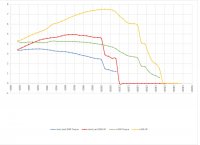

Pix (graph) worth a thousand words

I think this is one that kind if explains a few things people were questioning earlier.

10.6k and 11.6k the power outputs are very close.

The 262 is still is still gaining tq were the 361 is starting to plateau under the 10.6k rpm

9.5k, and 12.2k in the cutting range both saws are pretty much equal.

The 361 makes a bit more peak power, but the curve of the 262 looks more user friendly?

I think they may have videos of these saws cutting back to back?

@Duane(Pa)

@RI Chevy

sixonetonoffun

Super OPE Member

cus_deluxe

terms of service violator

- Local time

- 4:31 PM

- User ID

- 393

- Joined

- Jan 3, 2016

- Messages

- 5,643

- Reaction score

- 27,011

- Location

- Michigan

only because of the epic over-thinking and theory discussion goin on lol. i think its awesome to have a way to have concrete results that are repeatable. the conversation has veered away from what the dyno actually says into peoples interpretations and theories. which is cool, dont get me wrong, but i think people are missing the point honestly.More

cus_deluxe

terms of service violator

- Local time

- 4:31 PM

- User ID

- 393

- Joined

- Jan 3, 2016

- Messages

- 5,643

- Reaction score

- 27,011

- Location

- Michigan

variation from how one person runs a saw to another, IMO, will override any perceived differences in what the dyno says and what people think the dyno “should have said”. 066/660 beats a 395 on the dyno or whatever, but most would say a 395 will eat an 066/660s lunch. the problem is all the variables that get introduced once and bar and chain and operator are added to the equation. just appreciate the dyno for what it is, and what joe has done, which is make a thing that doesnt have brand loyalty etc. its just telling facts.

RI Chevy

Mastermind Approved!

- Local time

- 4:31 PM

- User ID

- 1254

- Joined

- May 7, 2016

- Messages

- 27,002

- Reaction score

- 67,801

- Location

- earth

I agree here. But as I stated, it wood be cool to go right from DYNO into wood to further confirm accuracy of DYNO. One would have to keep variables to absolute minimum. Same stick of wood, same chain, and same bar if possible, etc.

The DYNO is just 1 part of trying to predict how a saw will run.

The DYNO is just 1 part of trying to predict how a saw will run.

cuinrearview

Handy dood

- Local time

- 4:31 PM

- User ID

- 9248

- Joined

- Apr 16, 2019

- Messages

- 11,567

- Reaction score

- 80,208

- Location

- Dowling, MI

So let's take this part for what it is. A part. A very consistent part. Why muddy it?I agree here. But as I stated, it wood be cool to go right from DYNO into wood to further confirm accuracy of DYNO. One would have to keep variables to absolute minimum. Same stick of wood, same chain, and same bar if possible, etc.

The DYNO is just 1 part of trying to predict how a saw will run.

Similar threads

- Replies

- 13

- Views

- 2K