I was pretty skeptical about the compression measurements from these saws but after measuring the combustion chambers and doing a little math they check out.

To measure the chamber I cut a plexiglass disk to seal against the squishband and I fill the chamber with a fluid using a syringe. Many use ATF but windshield washer fluid evaporates really slowly and it's much nicer to work with and clean up. I usually use the blue stuff but all I had was the rain-x brand.

View attachment 317462 View attachment 317463

1ml = 1cc (cubic centimeter)

Chamber sizes are:

585 9.8cc

592 10cc

Now using the Ideal Gas Law PV = nRT

nRT is constant so we end up with:

P1 V1 = P2 V2

where:

P1 = base pressure

V1 = swept volume + squish volume + chamber volume

p2 = final pressure

v2 = squish volume + chamber volume

You can simplify and solve for P2:

P2 = P1*CR

where:

CR (corrected compression ratio) = V1/V2

To do this calculation you need a consistent set of units for distance and volume, metric units are much easier to deal with, we'll use mm and cc which will need an extra divide by 1000 to make mm^3 to cc. Since the volumes become a ratio V1/V2 we can use mixed units for the pressure (psi).

So you need to know the bore size, squish clearance, distance from the exhaust port to squish band and chamber volume.

Note P1 is base pressure at your altitude, I'm at ~800' so the base pressure is 14.26psi.

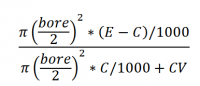

So substituting in the equations for the volumes and simplifying we get:

View attachment 317466

where (592):

Bore = bore diameter in mm, 55mm.

E = distance from top of the exhaust port to squishband, 1.045" = 26.543mm.

C = squish clearance, 0.022" = 0.5588mm.

CV = chamber volume, 10cc.

So for the the theoretical cranking compression is:

585 = 131psi

592 = 141psi