Well that pin was not out of the small end bearing, and I have no idea what it was from.

All I can think of it was left in the corner of the parts bin after the last saw that went through it and it was from an old pin bearing.

Got it running this arvo and damn don't it run.

Snappy, solid running saw that revs like a mutha-plucker!!!

I have not put the tacho on it yet but it was screaming and 4 stroking solid, My guess is up around 14500+

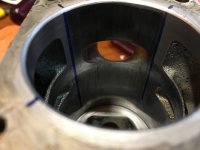

Gasket delete and a light sand of the base gave .019 squish and 170 psi which will be perfect for work saw use

I have stuck with the single port muffler but opened up the side port about 25% and put a better screen in.

I had trouble with my 064 once I ported it with a very open muffler and it came to life once I went back to a single port muffler on it. I am applying the same method to this one.

Mind you the single port is opened up plenty

I dont know why the ported saw likes less opening, but it does from what I have found.

The 2nd 044 I got has an OEM DP muffler on it so I may put the front on to see if it helps it tomorrow. If it does I will put a 2nd port on the side

I tried it with the max flow and it helped it spool up a bit but no real big change which makes me think it may want a bit more muffler