- Local time

- 5:31 AM

- User ID

- 325

- Joined

- Dec 30, 2015

- Messages

- 5,093

- Reaction score

- 25,364

- Location

- Centre County

I agree!! Lol. They use the flat thrust bearings on the swingarm style grinders. They seem to hold up well.View attachment 311711 Dresser pivots on the RS II leave something to be desired.

Grabbed these thrust ball bearings from McMaster Carr. Smooth for now. We shall see how they hold up to the harsh environment. (grit)

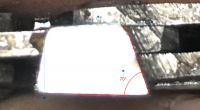

Might be a bit to much side plate angle. Will test is. Can soon change that.that looks like its going to be super grabby

Tilt dresser block towards motor to increase forward lean. Tilt block back toward operator to decrease... I use scribe mark, along with a snug adjustable wrench to control block while tightening holding bolt.I’ve been working on trying to profile a wheel on a newer rs2 that I purchased. Just a little too much forward lean at the moment. View attachment 313912View attachment 313913

Tilt dresser block towards motor to increase forward lean. Tilt block back toward operator to decrease... I use scribe mark, along with a snug adjustable wrench to control block while tightening holding bolt.

I disagree. And I know a lot of folks are fast to say you don’t want any lean or only 3 degrees, I found that chains like that don’t cut well after the first tank. With lean like you have it will self feed with higher rakers and still self feed when that corner isn’t perfect anymore. I much prefer angles like that vs no lean!I’ve been working on trying to profile a wheel on a newer rs2 that I purchased. Just a little too much forward lean at the moment. View attachment 313912View attachment 313913

I did the whole chain like this to see how it performs. I do have my other rs2 set up with less angle. Have always been happy with it…but it’s always good to try new little tweaks.I disagree. And I know a lot of folks are fast to say you don’t want any lean or only 3 degrees, I found that chains like that don’t cut well after the first tank. With lean like you have it will self feed with higher rakers and still self feed when that corner isn’t perfect anymore. I much prefer angles like that vs no lean!

I’d thin the wheel down a little bit so you can lower the chain and roll the cutter down into it some more if you want it to last longer. I agree that you want a little bit of forward lean to keep pulling itself in