blades

Super OPE Member

- Local time

- 2:45 PM

- User ID

- 7181

- Joined

- Aug 30, 2018

- Messages

- 395

- Reaction score

- 664

- Location

- Leroy, WI

To the op, I am a pro sharpening of some 30+ years shop. On avg. couple hundred chains a month + a whole ot of other stuff. My take- square grinders ton of fiddling, redressing wheel and such, difficult to get left and right cutters equal, also a lot of times you have to come back and clean out the gullet - slow not for a production environment. I have a Silvey, had Simington seldom use it for production work. Oregon/ Tecomec ( the actual mfg) are decent , have better motors than all the other clones- specs seem to run a bit tighter also- perfect no but better than most others. Every single chop style grinder a has the same problem, wear in the chain clamping system and tooth stop/locator. If you use it enough the the head pivot point starts getting some play also. I generally wear out a grinder or 2 a year. and those swiveling bases wear as well.

I have looked at the various auto grinders. Just can't justify costs, but that's just me. As with anything auto you have to stay on top of it even the Franzen. Semi auto would be a better description.

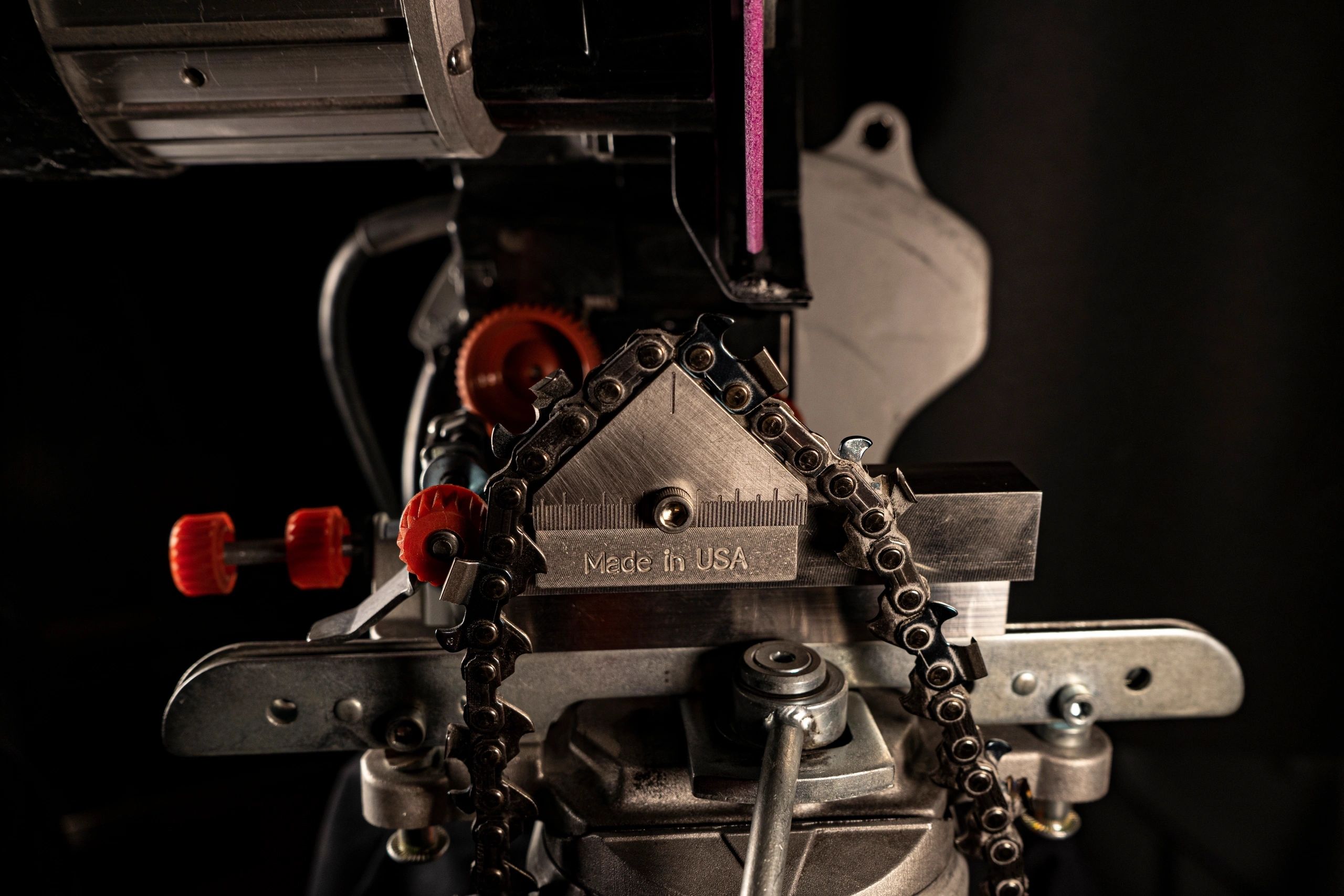

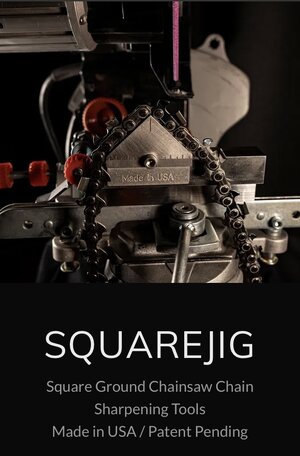

Square VS Round = Chevy/Ford/ Dodge. My op, square cuts real nice but dulls quicker than round ( I process about 8 cords or so a year as I heat my home with wood) Touching up a round chain is fairly simple in the field, Sq not so much, most never master hand filing of either. I see the results on a daily basis. I can by dressing the vitrified wheels and set up make a pretty good sq grind on the chop style grinders . There is a jig being sold by a member here for SQ grinding on chop style grinders- I haven't coughed up the $300? for it. Looks interesting.

The biggest differance between the two styles grinder ( other than wheel orientation) is the angle on the side plate in the horzontal plane- sharper with the sq grinder. But like any cutting tool the more acute the edge the quicker it wears. Chris

I have looked at the various auto grinders. Just can't justify costs, but that's just me. As with anything auto you have to stay on top of it even the Franzen. Semi auto would be a better description.

Square VS Round = Chevy/Ford/ Dodge. My op, square cuts real nice but dulls quicker than round ( I process about 8 cords or so a year as I heat my home with wood) Touching up a round chain is fairly simple in the field, Sq not so much, most never master hand filing of either. I see the results on a daily basis. I can by dressing the vitrified wheels and set up make a pretty good sq grind on the chop style grinders . There is a jig being sold by a member here for SQ grinding on chop style grinders- I haven't coughed up the $300? for it. Looks interesting.

The biggest differance between the two styles grinder ( other than wheel orientation) is the angle on the side plate in the horzontal plane- sharper with the sq grinder. But like any cutting tool the more acute the edge the quicker it wears. Chris