Terry Syd

Pinnacle OPE Member

- Local time

- 7:44 PM

- User ID

- 575

- Joined

- Jan 18, 2016

- Messages

- 1,589

- Reaction score

- 5,987

- Location

- Comboyne, NSW Australia

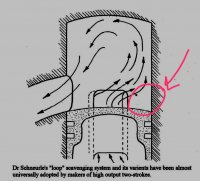

Some guidelines from Blair on transfers. There is a wealth of information in his work - stuff that has been empirically confirmed. You don't have to understand the math, it is the theories in the text, supported by the graphs and pictures that tell the real story. The math is for the next engineer to use on a new design.

3.5.5.1 The main transfer port

The orientation of the main port, which is the scavenge port immediately beside the exhaust port, is already stated as the designer's first priority and this has some potential for empirical guidance. If one examines the port plan layouts of all of the cylinders known to provide successful scavenging, several factors stand out quite noticeably:

(a) The upsweep angle of the main port, UPM, is rarely larger than 10°.

(b) The value of AM2 is usually between 50° and 55°.

(c) The target point for MT2 is usually between 10% and 15% of the cylinder bore dimension, BO.

(d) The target point for MT1 is approximately on the edge of the cylinder bore.

(e) The port is tapered to provide an accelerating flow though the port, i.e., AMI is greater than AM2, and AMI is rarely larger than 70°.

(f) The larger the angle, AMI, the more the target point, MT1, is inside the cylinder bore. The narrower the angle, AMI, the farther outside the cylinder bore is the target

3.5.5.1 The main transfer port

The orientation of the main port, which is the scavenge port immediately beside the exhaust port, is already stated as the designer's first priority and this has some potential for empirical guidance. If one examines the port plan layouts of all of the cylinders known to provide successful scavenging, several factors stand out quite noticeably:

(a) The upsweep angle of the main port, UPM, is rarely larger than 10°.

(b) The value of AM2 is usually between 50° and 55°.

(c) The target point for MT2 is usually between 10% and 15% of the cylinder bore dimension, BO.

(d) The target point for MT1 is approximately on the edge of the cylinder bore.

(e) The port is tapered to provide an accelerating flow though the port, i.e., AMI is greater than AM2, and AMI is rarely larger than 70°.

(f) The larger the angle, AMI, the more the target point, MT1, is inside the cylinder bore. The narrower the angle, AMI, the farther outside the cylinder bore is the target