- Local time

- 7:11 PM

- User ID

- 25442

- Joined

- Nov 16, 2022

- Messages

- 266

- Reaction score

- 960

- Location

- Long Beach, IN

Received a clone 372XP the other day to learn how Husky's are set up and to have another go at porting. Ran it for ~ 5 minutes out of the box with 24:1 synthetic, worked and sounded right. Here's what I've found so far in a teardown:

- Unlike a recent G660 clone I ported, none of the fasteners on this one were loctited

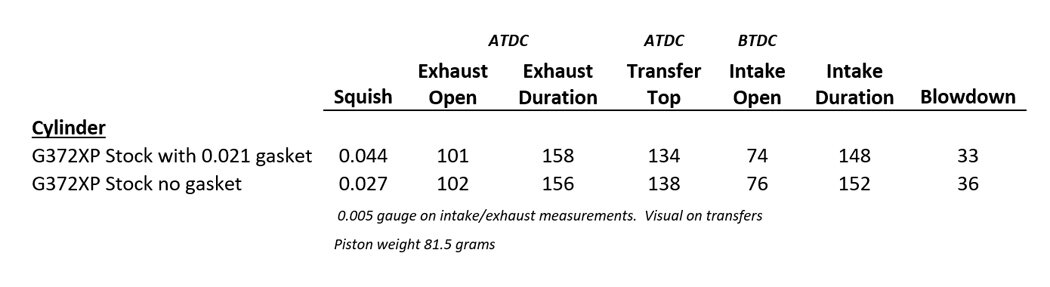

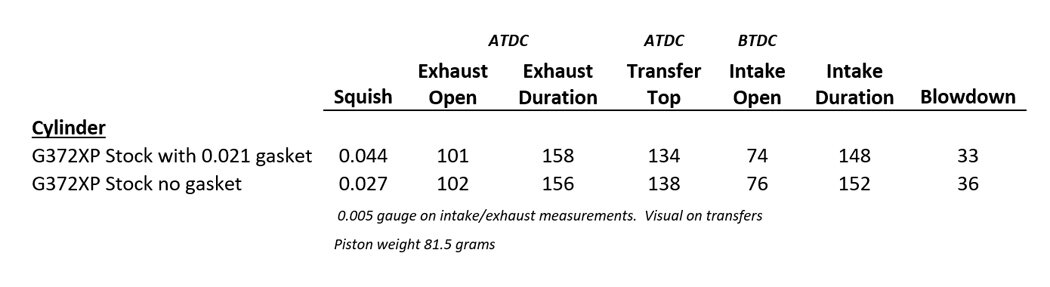

- Timing as built with and without a base gasket. Very high transfer numbers seem odd

- Piston and single ring look OK, however there was some minor scuffing on the intake and exhaust sides:

Cylinder intake, some ragged edges are cause of minor scuffing on piston

-Cylinder Exhaust, more ragged edges

Muffler is completely open inside, here's a concept for a deflector (thanks @drf256 !) to braze on the top. Gasket opening on the cylinder discharge is 0.94 square inches, plan is to drill a pair of 3/8" holes in the top of the muffler, open these up to an oval, then braze on the deflector.

Many thanks to folks that have posted tips on porting this cylinder. Goal for port timing numbers is 102/120/78. Special thanks to @huskihl for info on this thread that shows moving the transfers up to 120: https://opeforum.com/threads/372xp-port-timing-numbers.29031/

New Husqvarna 577 57 24-01 piston pin bearing will be used in rebuild, plan is to keep everything else stock.

- Unlike a recent G660 clone I ported, none of the fasteners on this one were loctited

- Timing as built with and without a base gasket. Very high transfer numbers seem odd

- Piston and single ring look OK, however there was some minor scuffing on the intake and exhaust sides:

Cylinder intake, some ragged edges are cause of minor scuffing on piston

-Cylinder Exhaust, more ragged edges

Muffler is completely open inside, here's a concept for a deflector (thanks @drf256 !) to braze on the top. Gasket opening on the cylinder discharge is 0.94 square inches, plan is to drill a pair of 3/8" holes in the top of the muffler, open these up to an oval, then braze on the deflector.

Many thanks to folks that have posted tips on porting this cylinder. Goal for port timing numbers is 102/120/78. Special thanks to @huskihl for info on this thread that shows moving the transfers up to 120: https://opeforum.com/threads/372xp-port-timing-numbers.29031/

New Husqvarna 577 57 24-01 piston pin bearing will be used in rebuild, plan is to keep everything else stock.

Last edited: