- Local time

- 4:04 PM

- User ID

- 25442

- Joined

- Nov 16, 2022

- Messages

- 279

- Reaction score

- 1,036

- Location

- Long Beach, IN

Figured I start with a 1/2" hole reamed out a bit with a file to start with. I can make this bigger later if needed.

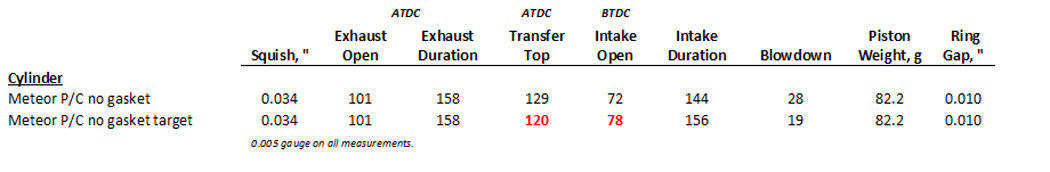

Measurements were taken with ring on top of piston & base gasket removed. This Meteor cylinder and piston look to be of much higher quality than the P/C this saw was built with.

I'll use the Holzfforma jug to practice porting on transfers and to see if taking it down to 120 degrees breaks through the tunnel wall. I may run it if it doesn't.

Thanks Shaun, I've read that posted by others as well.

What can you suggest to prevent such flaking with a Meteor? Or would it be better to leave it as is?

I'm with Shaun on this one. If a person spends the extra money to buy a Meteor or Hyway cylinder, then I would leave the ports alone and hope for the best. I have ported several farmertec jugs with good success.Some have luck with grinding the plating away before going at the port with a carbide burr so they don't lift the plating when removing the port material.

Personally I would stick with the cylinder that came on the saw, I haven't run into any problems with the plating flaking on them.

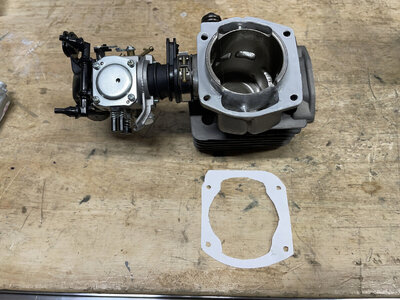

Now I'm not sure if anyone has ever noticed or just never say anything about it but the cylinder base gasket protrudes a 1/8 into the lower transfer tunnels that alone is a power robbing bottle neck I do plan on doing a base gasket delete a open up the lower transfers a bit and clean the tunnels up nothing crazy there uppers I'll leave for now until I run the saw for a few weeks then I'll put my timing wheel on the saw and go from there they did run the saw before it left the factory glad they didn't run it to long with all the ruff edging but still feel good about the saw pretty well put together everything was nice and tight has pretty good comparison I'll put a compression gauge on it after tomorrow and get numbers for everyone I'm guessing without base gasket it should at least be 150psi or 160psi I'd be pretty surprised if it had more than that.

The aliment is pretty good with mine some what the gasket is about the same on the case as the cylinder im going out to the shed here in a few and start working on the ports I'm also thinking about popping the flywheel off and advancing that to something that I've always had to do with Stihl saws.It's not only the gasket, but I've found that the case is never the size of the lower transfers, especially with the BB cylinders.

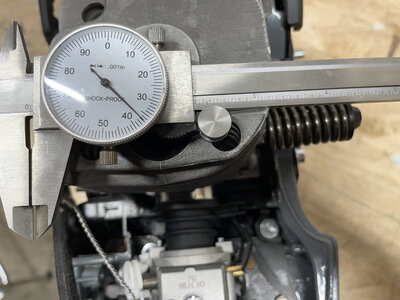

I did not check timing numbers before I tore it down I didn't care there all pretty close to the same Im putting it back together I forgot to take pictures before I stuck the cylinder back on my brain was pre occupied of all the stuff I had to do do to get the intake and tank handled to get along with each other but don't worry all I did to the intake and exhaust ports was get rid of the ugly that was it on those I did open out the lower transfers but how I did mine is completely different from everyone else so not showing those to anyone just yet the base gasket is out and will never going back these things suck for squish if I get a brake today from everything else I'll try and at least post som mor pics of squish and exhaust port and compression sorry ago for not having mor details on timing numbers I will put my timing flywheel on it but that will be later on after I've ran a few tanks through it.@MG porting , what were your timing numbers on this saw as as built and how you received it?