You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Husqvarna 2100 thread

- Thread starter Brewz

- Start date

nv656

Super OPE Member

- Local time

- 12:21 PM

- User ID

- 27693

- Joined

- Oct 14, 2023

- Messages

- 247

- Reaction score

- 445

- Location

- Nevada

Fun fact, I purchased a non chain brake nos cover a while back that had the same casting numbers as the chain brake cover 2101. Leading me to believe that they were still making non chain brake covers well into the 2101 saws and just modifying the covers

Here’s a picture of all 3

Here’s a picture of all 3

singinwoodwackr

Pinnacle OPE Member

- Local time

- 1:21 PM

- User ID

- 34279

- Joined

- Sep 14, 2025

- Messages

- 753

- Reaction score

- 2,184

- Location

- moon

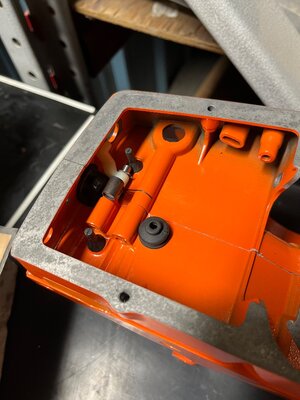

So, that’s what the tanks are supposed to look likeA flavor cylinder, nos tank

edisto

Super OPE Member

Damn, that's a handsome looking saw.

singinwoodwackr

Pinnacle OPE Member

- Local time

- 1:21 PM

- User ID

- 34279

- Joined

- Sep 14, 2025

- Messages

- 753

- Reaction score

- 2,184

- Location

- moon

The brake internals for the 2101 are the same as the 281/288 and are floating around. The flag handles are the hard parts to find.

- Local time

- 12:21 PM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,012

- Reaction score

- 9,738

- Location

- Northern Idaho, Ehh

It may be dumb, but just think how many 2100/2101s have been resurrected from problem piles just in this thread alone!Starting with just a bare case/crank with crusty bearings was D U M B dumb.

- Local time

- 12:21 PM

- User ID

- 26879

- Joined

- Jun 7, 2023

- Messages

- 1,741

- Reaction score

- 5,029

- Location

- Norcal

Mine's got a part on it from every problem pile ever. Learned a lot doing it that way and it only cost maybe triple what starting with a parts/repair saw would have.It may be dumb, but just think how many 2100/2101s have been resurrected from problem piles just in this thread alone!

Last edited:

- Local time

- 12:21 PM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,012

- Reaction score

- 9,738

- Location

- Northern Idaho, Ehh

Good to know I am not the only oneMine's got a part on it from every problem pile ever. Learned a lot doing it that way and it only cost maybe triple what starting with a parts/repair saw would have.

edisto

Super OPE Member

Starting with just a bare case/crank with crusty bearings was D U M B dumb.

NOW you tell me...

- Local time

- 12:21 PM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,012

- Reaction score

- 9,738

- Location

- Northern Idaho, Ehh

Mine's got a part on it from every problem pile ever. Learned a lot doing it that way and it only cost maybe triple what starting with a parts/repair saw would have.

I agree...I could have bought a project 2100 that might not have needed a lot to get going, but I think going this route helped me develop a lot of confidence to get really deep into the saw and build it back out. I found that changing bearings is not as bad as I thought even without the correct tools. I used two boards, cargo straps and a rubber mallet to get the case halves back together, it was a hokey setup, but I did it (I have the correct case splitting and setting tools now!).NOW you tell me...

Through this project I learned a lot about chainsaws, it was a lot of work for me and helps me have a better idea/appreciation for future project saws! So I ultimately look at it, I didn't just pay for expensive used parts, I paid for experience that I have used on saws I have worked on since!

- Local time

- 12:21 PM

- User ID

- 26879

- Joined

- Jun 7, 2023

- Messages

- 1,741

- Reaction score

- 5,029

- Location

- Norcal

That's exactly why I went ground up with a 2100. Only thing I can give undivided attention to is what my hands are doing.I agree...I could have bought a project 2100 that might not have needed a lot to get going, but I think going this route helped me develop a lot of confidence to get really deep into the saw and build it back out. I found that changing bearings is not as bad as I thought even without the correct tools. I used two boards, cargo straps and a rubber mallet to get the case halves back together, it was a hokey setup, but I did it (I have the correct case splitting and setting tools now!).

Through this project I learned a lot about chainsaws, it was a lot of work for me and helps me have a better idea/appreciation for future project saws! So I ultimately look at it, I didn't just pay for expensive used parts, I paid for experience that I have used on saws I have worked on since!

I highly recommend others do the same (with some other saw). There are several saws that are yesterday's tech, but not day before yesterday's tech that would be much better choices. Affordability and availability of NOS, used and aftermarket parts is key.

- Local time

- 12:21 PM

- User ID

- 27954

- Joined

- Nov 24, 2023

- Messages

- 3,012

- Reaction score

- 9,738

- Location

- Northern Idaho, Ehh

Yeah, I have a few 50's-60s' McCulloch saws that I am redoing from the ground up. They are not necessary the most desirable or have the greatest stock of aftermarket parts, but they will give me a great opportunity to learn metal repair and painting, if I screw up, no big loss. If it works out then I will have learned something and have a nice looking/running saw afterwards!I highly recommend others do the same (with some other saw). There are several saws that are yesterday's tech, but not day before yesterday's tech that would be much better choices. Affordability and availability of NOS, used and aftermarket parts is key.

- Local time

- 12:21 PM

- User ID

- 26879

- Joined

- Jun 7, 2023

- Messages

- 1,741

- Reaction score

- 5,029

- Location

- Norcal

.

Husqvarna 2100/285cd Parts Lot | eBay

Husqvarna 2100/285 cd parts lot. Look closely at pics for condition. I’m not 100% that parts cross over both platforms. If you need any more pics please message me in advance not 5 minutes before the end of auction.

www.ebay.com

Similar threads

- Replies

- 6

- Views

- 472

- Replies

- 8

- Views

- 1K