- Local time

- 9:19 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,878

- Reaction score

- 59,128

- Location

- Croatia

What Philbert said.Ok guys this should fall inline with the thread topic here I hope. I have a new to me grinder I purchased from another member here that worked fine for them I have no doubt. Only difference is they were using a CBN wheel on it where im using an Oregon.

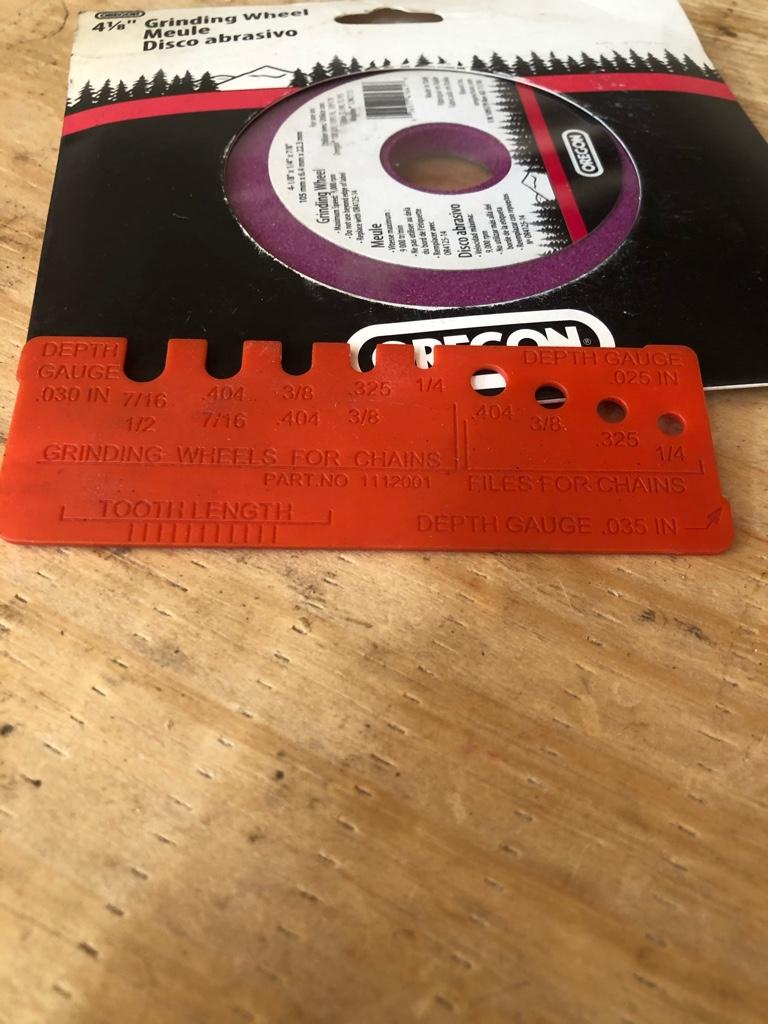

The grinder is an Oregon model #108181. I’ve dressed 2 wheels for the .325 and 3/8 per the little orange guide that comes with the grinder. Ground the chains then checked the rakers. Angle is set to 30. The motor head arm is fixed position and do not know what it is.

I ground three chains and all looked good but once you put them in the wood they wont cut and will actually start smoking. Im doing something majorly wrong.

I can file them sharp by hand no problem but this grinding thing is new to me any help would be appreciated.

There seems to be next to no beak on those cutters.