I had a bit that was way too aggressive in aluminum. It would just about suck the drill press down.

That's always fun!

Drilling Aluminum is like drilling wood, corkscrew effect.

I have wondered if faster is better or not. I hear cutting metal too fast will overheat the cutter, but then they say you can cut hardened steel so fast the chips glow without risking damage to the cutters. The only problem I see there is red hot chips can stick to the cutters allowing more time for heat transfer.

Yes. And learn better macro picture taking skills, I know it is not easy. Maybe we can teach each other something.

I see sparks flying every other day processing grey cast iron (technicaly merely pig iron though!), believe me when I say that not even Solid-Carbide likes sparking mediums on the long run!

Also, whether or not and how efficiently a tool transfers the friction heat into the chips depends on many factors: tools core material, coating, cutter shape angles and sharpness, the material being processed, ...

Just because a tool can endure high rpm/feed/heat without liquid cooling doesn't mean it wouldn't perform equally well but with a longer lifespan with liquid cooling.

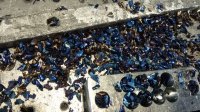

Look at the chip pictures I posted, closely!

They all start cold and then blue as they get cut, then the chip breakage (with spindle retract) engages letting the workpiece and drill bit cool down - on the next feed cycle the chips start flowing cool and again become thermally blued as the cut progresses.

The time it takes the machine to retract from feed and return to feed again is a fraction of a second, but it is enough to allow the generated heat to both dissipate and spread keeping the drill bits tip at an acceptable work temperature.

There are many variables that influence tool life, most can be ignored or ballparked by simply adding massive liquid cooling.

In regards to that video.

The top of an anvil is surface hardened from hammering on it.

Also, a good anvil is not mild steel , far from it.

I have seen vintage anvils broken in half, mild steel doesn't do that.

The rpm may have been a bit too high for that diameter mill head - staged for the wow effect?!

The biggest I run is a TungAlloy 67mm 6 cutter head at 1155rpm max in pig iron without cooling and it tends to spark occasionally and chip/wear the cutters fast.

Quite often the manufacturers specs for their tools rpm/feed are painfully exaggerated - one must keep in mind that manufacturer tool specs are the MAX under perfect conditions!

Apologies for the lengthy post!

I am a metal worker and machinist, it is kinda my kink.