Drill bit tip angles are pretty important I think, harder the material the steeper the point in my experience. A 118* tip in stainless has never worked well for me. Fein slugger cutting paste seems to work good and I have buttercut too but haven’t tried many other products. I like crown all 4 for lighter stuff and honing.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Drill bits for metal and using them properly

- Thread starter Nutball

- Start date

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

Funny enough, I don't own a single left hand/CCW drill bit.Some of us are just meant to not have nice things. The way my stuff gets abused because of lack of access or other factors...... I just buy the cheapest crap I can find and re shape or sharpen as many times as needed. Most the time anyway.

Now if I'm lucky enough to be able and use my drill press. Well then I will use some better bits I inherited from my grandpa. But for freehand stuff. Forget about it I'll stick to the cheap stuff and wear my safety glasses.

View attachment 358594 View attachment 358595 View attachment 358596 View attachment 358597

Steven

That/those broken ones can be saved.

Stevetheboatguy

mountain dew and ibuprofen please

- Local time

- 6:30 PM

- User ID

- 2591

- Joined

- Feb 6, 2017

- Messages

- 1,797

- Reaction score

- 8,416

- Location

- Nw IL

Funny enough, I don't own a single left hand/CCW drill bit.

That/those broken ones can be saved.

I've gotten to be a expert at saving snapped bits. Have some that the flute is only a inch or so long anymore

I bought a decent irwin left hand extraction kit. It comes in very handy for my line of work. Whole new ball game trying to sharpen one of those buggars. Have not mastered them by any means.

Steven

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

Lol, You gotta grind those LH drill bits while doing a handstand - easy peasy!I've gotten to be a expert at saving snapped bits. Have some that the flute is only a inch or so long anymore

I bought a decent irwin left hand extraction kit. It comes in very handy for my line of work. Whole new ball game trying to sharpen one of those buggars. Have not mastered them by any means.

Steven

Being drunk grinding those works too though...

Nutball

Here For The Long Haul!

- Local time

- 6:30 PM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,848

- Location

- Mt. Juliet, TN

I'm always pushing the limits of crappy cameras. It's a bit of a hassle, but if you know what you are doing, you can use the short comings of the camera against itself. I won't say the pictures I posted of drill bits were all that good because I only gave it one shot after setting up lights and cheating with an external lens, but I didn't go back to make sure they turned out right before loading onto the computer to edit.Just to comment on the quality of my pictures.

My Sony Ericsson Elm DUMBPHONE of 12 years with a mere 5MP camera had a selective macro mode and I could take pictures as close as 1" from the object - razor sharp pictures of a blank paper sheet showing all the grooves and fiber strands of the papers surface.

Sadly my Elm died on me and I got a "smartphone" (???!!!).

That stupid thing makes crappier pictures at 20MP than my still working K750i at 2MP. And the quality of the so called smartphone camera is extremely inconsistent, it rarely auto zooms correctly and most times just focuses on anything BUT the object I am taking a picture of.

I always said that smartphones are for dumb people, now I am one of them!

Don't hold back, I like details. Too many people leave out the details as if they are unnecessary or frowned upon, but things work the way they work, and sometimes the smallest of details are quite important.Apologies for the lengthy post!

I am a metal worker and machinist, it is kinda my kink.

- Local time

- 7:30 PM

- User ID

- 21

- Joined

- Dec 4, 2015

- Messages

- 5,336

- Reaction score

- 28,488

- Location

- In a meeting

I use the free Mag. Light app on my phone ……… it really doesn’t get any easier

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

KcChiefs2019

Well-Known OPE Member

- Local time

- 6:30 PM

- User ID

- 10451

- Joined

- Sep 13, 2019

- Messages

- 49

- Reaction score

- 65

- Location

- Illinois

I found some useful info in these series of 3 videos. Bout pull my hair out tho by the end. I have learnt a few things over the years. When it comes to drilling metal. Number 1 knew exactly what type of metal it is u want to drill threw. If u don’t know what it is, then start out medium pressure and slow rpm’s. Stainless always slow slow slow, good amount pressure once it starts cutting. Pressure means everything compared to speed for tht type metal.

Nutball

Here For The Long Haul!

- Local time

- 6:30 PM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,848

- Location

- Mt. Juliet, TN

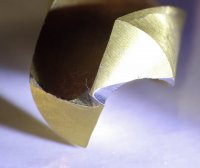

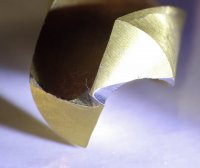

I had some hot rolled steel from lowes to drill as well as whatever zinc plated steel is used on boat trailer winches. I reached for a new harbor freight 1/2" bit that comes in the 21pc set for $10. It had the non cutting tip, so I tried grinding a cutting tip into it.

Good ol autofocus missed the mark

It seems like a non aggressive bit because it took a lot of pressure just to get chips rather than a nice long coil. I ran it at 200rpm, and would have to stop to let it cool every 5-10 seconds or so. It's annoying how the 2 flute bits like to make a triangular hole.

Good ol autofocus missed the mark

It seems like a non aggressive bit because it took a lot of pressure just to get chips rather than a nice long coil. I ran it at 200rpm, and would have to stop to let it cool every 5-10 seconds or so. It's annoying how the 2 flute bits like to make a triangular hole.

Al Smith

Here For The Long Haul!

- Local time

- 7:30 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

Because I worked in an auto engine plant I have coffee cans full of solid carbide CNC drill bits .Those will go through the hard steel bars like a hot knife through butter .You can use a high quality high speed or alloy steel drill bits which work better in a drill press ."Tap magic " often works better than cutting oil .Don't dilly dally .Start the cut then put the down pressure on it until you are through the bar .If you play with it all it will do is further harden the steel

Funky sawman

Pony Power

- Local time

- 4:30 PM

- User ID

- 2609

- Joined

- Feb 10, 2017

- Messages

- 2,434

- Reaction score

- 9,758

- Location

- North idaho

My drilling method is push as hard as I can, with no lube........

Al Smith

Here For The Long Haul!

- Local time

- 7:30 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

I might add a little tip .Often times breaking through one side of the bar groove will clean the edge off the drill bit .Try putting a piece of sheet metal in the groove and use another piece of scrap steel on the other side that way you don't have a delayed cut .

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

That is close, but You made a rookie mistake.I had some hot rolled steel from lowes to drill as well as whatever zinc plated steel is used on boat trailer winches. I reached for a new harbor freight 1/2" bit that comes in the 21pc set for $10. It had the non cutting tip, so I tried grinding a cutting tip into it.

Good ol autofocus missed the mark

View attachment 359544

View attachment 359545

View attachment 359546

It seems like a non aggressive bit because it took a lot of pressure just to get chips rather than a nice long coil. I ran it at 200rpm, and would have to stop to let it cool every 5-10 seconds or so. It's annoying how the 2 flute bits like to make a triangular hole.

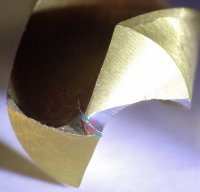

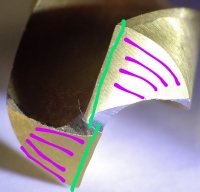

1) Do not grind the "cross cut" so deep that they intersect! On a 1/2" drill bit leave an about 1mm untouched center (circled in red) otherwise You risk breakage of the weakened center thus losing the bits tip.

2) Grind the "cross cut" a little further into the cutting edge so that You get a secondary cutting edge which will also be more resilient to wear (blue lines)

But You get the idea.

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

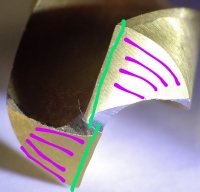

To get a better bite of a factory ground new drill bit regrind it a little.

Start grinding from the back side of the cutter edges (marked in violet) twisting the bit so that You grind towards the cutting edge but without touching the factory ground cutting edges themselves (do not grind beyond the green lines).

The more material You remove in the violet marked area the more aggressive the drill bit will cut - it is like removing material from the rakers on a chainsaw chain!

DISCLAIMER ! ! !

EXTREME DANGER OF DRILL BIT TAKING TOO BIG A BITE AND WORKPIECE TEARING FREE AND/OR TOOL BREAKAGE ! ! !

Start grinding from the back side of the cutter edges (marked in violet) twisting the bit so that You grind towards the cutting edge but without touching the factory ground cutting edges themselves (do not grind beyond the green lines).

The more material You remove in the violet marked area the more aggressive the drill bit will cut - it is like removing material from the rakers on a chainsaw chain!

DISCLAIMER ! ! !

EXTREME DANGER OF DRILL BIT TAKING TOO BIG A BITE AND WORKPIECE TEARING FREE AND/OR TOOL BREAKAGE ! ! !

Al Smith

Here For The Long Haul!

- Local time

- 7:30 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

This is just for reference because I doubt seriously if many could not only find one but also could not afford one .This is a solid carbide CNC drill bit with lube holes which in use pump coolant through them .It's got a special grind on it .

In use what happens is they run a predetermined amount of holes then replaced .Might be a couple thousand .Then it's dressed and measured .If it's too short it gets scrapped .

As I mentioned a quality twist drill will work but not the kinds in a 5 piece set they sell for 5 dollars .You can find them on e-bay and they don't take a special grind but they won't drill 500 holes in a row ,maybe half a dozen .As another few options could be to use an end mill in a milling machine making a plunge cut or use a shaped stone with a die grinder .

In use what happens is they run a predetermined amount of holes then replaced .Might be a couple thousand .Then it's dressed and measured .If it's too short it gets scrapped .

As I mentioned a quality twist drill will work but not the kinds in a 5 piece set they sell for 5 dollars .You can find them on e-bay and they don't take a special grind but they won't drill 500 holes in a row ,maybe half a dozen .As another few options could be to use an end mill in a milling machine making a plunge cut or use a shaped stone with a die grinder .

Attachments

- Local time

- 7:30 PM

- User ID

- 522

- Joined

- Jan 12, 2016

- Messages

- 4,196

- Reaction score

- 27,500

- Location

- Iowa City

@Wilhelm do you have a picture of the wheel/machine you use to do the back cut “cross cut”?

I’ve always sharpened bits on a belt sander as the wheels on our bench grinder are always badly shaped (rounded for cleaning up tubing notches). So I’m not able to do the cross cut.

I’ve found on some large drilling operations on the lathe I have to grind the front of the flute at a less steep angle to make the bit less aggressive. I do this to keep it from biting and pulling the MT3 taper loose from the tailstock.

The drills and taps you sent me a long while ago are holding up well. It’s so nice to have a well curated metric setup in the land of inches.

I’ve always sharpened bits on a belt sander as the wheels on our bench grinder are always badly shaped (rounded for cleaning up tubing notches). So I’m not able to do the cross cut.

I’ve found on some large drilling operations on the lathe I have to grind the front of the flute at a less steep angle to make the bit less aggressive. I do this to keep it from biting and pulling the MT3 taper loose from the tailstock.

The drills and taps you sent me a long while ago are holding up well. It’s so nice to have a well curated metric setup in the land of inches.

Al Smith

Here For The Long Haul!

- Local time

- 7:30 PM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,683

- Reaction score

- 14,929

- Location

- North western Ohio

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

I use a diamond laced grinding stone dresser to get a sharp corner on my wheel - yes, it can be tedious if the wheel is f-ed up.@Wilhelm do you have a picture of the wheel/machine you use to do the back cut “cross cut”?

I’ve always sharpened bits on a belt sander as the wheels on our bench grinder are always badly shaped (rounded for cleaning up tubing notches). So I’m not able to do the cross cut.

...

The drills and taps you sent me a long while ago are holding up well. It’s so nice to have a well curated metric setup in the land of inches.

I can get some pictures, I'll look into it.

What did I send You, HSS-Co or Solid-Carbide?

I can't recall, sorry.

I am glad You are getting some use out of whatever it is I sent You.

Last edited:

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

I am curious, if I may ask:This is just for reference because I doubt seriously if many could not only find one but also could not afford one .This is a solid carbide CNC drill bit with lube holes which in use pump coolant through them .It's got a special grind on it .

In use what happens is they run a predetermined amount of holes then replaced .Might be a couple thousand .Then it's dressed and measured .If it's too short it gets scrapped .

As I mentioned a quality twist drill will work but not the kinds in a 5 piece set they sell for 5 dollars .You can find them on e-bay and they don't take a special grind but they won't drill 500 holes in a row ,maybe half a dozen .As another few options could be to use an end mill in a milling machine making a plunge cut or use a shaped stone with a die grinder .

- bit manufacturer?

- Titanium coated?

- what material is the bit being used in?

5D and longer flutes tend to feature internal cooling, although 3D can have it as well.

- Local time

- 1:30 AM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,888

- Reaction score

- 59,180

- Location

- Croatia

I know this can happen, same issue with big tapered drills on drill presses.@Wilhelm

I’ve found on some large drilling operations on the lathe I have to grind the front of the flute at a less steep angle to make the bit less aggressive. I do this to keep it from biting and pulling the MT3 taper loose from the tailstock.

CNC mills have pull studs, can't happen unless the mill is defective.

![DSCN1285[1].JPG](/data/attachments/359/359977-e4eb7edf7a6f6058d165015e515c35f0.jpg?hash=5Ot-33pvYF)