Nutball

Here For The Long Haul!

- Local time

- 2:18 AM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,042

- Reaction score

- 11,036

- Location

- Mt. Juliet, TN

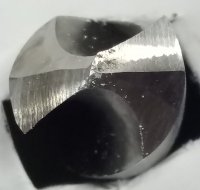

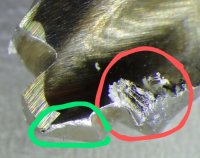

I was just drilling some holes in Stihl bars to fit on Echo saws, and my 1/4" bit had trouble advancing after the tip easily drilled its way in. I remembered I may have damaged it in the past when drilling 2 holes close together, so I got out a new bit and started a new hole. It worked great for about 2/3 through the bar, then started having similar difficulties with squeaking and not cutting well. Occasionally it would start cutting better in other holes, but got to the point where I'd basically ram it several times just to finish the holes.

I was using WD40 and short durations of drilling less than a second long to keep the bit cool. Maybe the RPM was too high? Maybe the steel had uneven hardening? I'm pretty sure I avoided any rivets and blued parts of the bar. I was drilling at 870rpm.

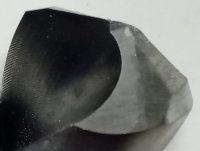

I also had a regular washer I was trying to drill out with a 1/2" drill bit. I think I got 1 washer drilled, but the next would rather cut the drill bit down to size than let the drill widen the hole.

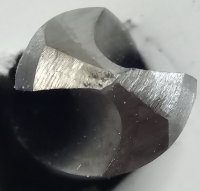

Am I using the wrong kind of drill bit? Wrong rpm? Poor quality bits?

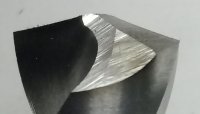

Any tips on how to sharpen drill bits?

I was using WD40 and short durations of drilling less than a second long to keep the bit cool. Maybe the RPM was too high? Maybe the steel had uneven hardening? I'm pretty sure I avoided any rivets and blued parts of the bar. I was drilling at 870rpm.

I also had a regular washer I was trying to drill out with a 1/2" drill bit. I think I got 1 washer drilled, but the next would rather cut the drill bit down to size than let the drill widen the hole.

Am I using the wrong kind of drill bit? Wrong rpm? Poor quality bits?

Any tips on how to sharpen drill bits?