jeffkrib

Well-Known OPE Member

- Local time

- 4:04 AM

- User ID

- 24818

- Joined

- Aug 23, 2022

- Messages

- 28

- Reaction score

- 78

- Location

- Sydney Aus

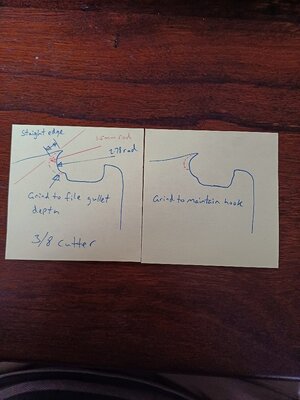

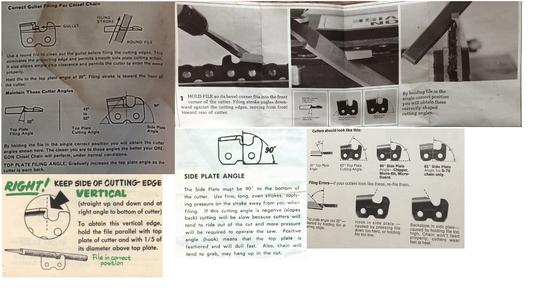

Thanks Philbert, yes I understand the file diameter controls the curve in the gullet. I keep my stone wheels the same radius as the file size.

If your swapping between grinding and filing this makes sense but if I'm grinding with a CBN wheel which gives a 1.5mm radius for all size chains are there any other considerations. Would the only down side be noticed when swapping between grinder and file?

With a smaller radius wheel the larger chains would have a straight line from the cutting edge before hitting the gullet as aposed to a curve immediately after the cutting edge.

Is the gullet similar to a chip breaker on a lathe or milling tool?

cadem.com

cadem.com

If your swapping between grinding and filing this makes sense but if I'm grinding with a CBN wheel which gives a 1.5mm radius for all size chains are there any other considerations. Would the only down side be noticed when swapping between grinder and file?

With a smaller radius wheel the larger chains would have a straight line from the cutting edge before hitting the gullet as aposed to a curve immediately after the cutting edge.

Is the gullet similar to a chip breaker on a lathe or milling tool?

Chip breaker and how chip breaking happens - CNC turning - Cadem

Chip breaking not happening? Maybe you're using the wrong insert, with the wrong chip breaker geometry, or wrong feed rate. An explanation...