You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chainsaw grinder questions, tips, tricks, and pics!!!!

- Thread starter Khntr85

- Start date

Squish9

Pinnacle OPE Member

- Local time

- 10:49 PM

- User ID

- 28596

- Joined

- Feb 27, 2024

- Messages

- 331

- Reaction score

- 1,468

- Location

- Australia

Round file but I am referring to the finished cutter shape, not the angles of the grinderAre you talking square chain? I was referring to round grinder angles

C83/85 for example has a 30 degree top plate angle (filing angle) 45 degree side plate angle (hook) and a 45 top plate cutting angle (face of the top plate).

I can't accurately measure the factory C83 but it's in the 45-50 degree range

I don't have access to any of the soft woods where more side plate angle might be an advantage. I can only judge it by how it performs in the wood I cut, but my general experience is that less hook is much more durable without loosing any cut speed. Normally it increases the cut speed when in the 75-85 degree range if you can maintain top plate cutting angle in the 50-60 degree range

chipper1

Here For The Long Haul!

- Local time

- 6:49 AM

- User ID

- 1463

- Joined

- Jun 25, 2016

- Messages

- 6,391

- Reaction score

- 24,031

- Location

- Grand Rapids Mi

Thats not been my experience, and I've done quite a bit of timed tests mostly in hardwood as that's 95% of what I cut.I can only judge it by how it performs in the wood I cut, but my general experience is that less hook is much more durable without loosing any cut speed. Normally it increases the cut speed when in the 75-85 degree range if you can maintain top plate cutting angle in the 50-60 degree range

That being said, durability is a great factor to consider over a day of cutting, sitting down to touch up a chain every couple tanks decreases productivity. Some days, I look forward to those breaks, and will even stoop to only filling the saw 1/2 to 3/4 full.

I'd like to see your chains vs the x-cut chain in timed cuts.

Philbert

Chainsaw Enthusiast

- Local time

- 5:49 AM

- User ID

- 737

- Joined

- Jan 30, 2016

- Messages

- 5,054

- Reaction score

- 21,662

- Location

- East Dakota

A big advantage of sharpening one’s own chains is being able to customize them for one’s own preferences: speed, longevity, types of cutting, species and condition, powerhead, ease of sharpening, tools available, etc.From the beginning of the introduction of grooving saw chains, which were initially sharpened with flat files, the recommended side plate angle was 90°.

Also, when chains sharpened with round files appeared, of which the Oregon chipper eventually captured the largest market, the required side plate angle was also 90°. Deviation from this value was considered a sharpening error.

Today's Oregon square ground (3/8) and chipper (.404) chains also have a recommended side plate angle of 90°. (85° for square filed .404 and 3/4 chipper for harvesters).

Many times you've probably seen the video (anyone have a printed brochure perhaps?), where Vallorbe recommends 90° for “hard” wood, and even 100° (backslope) for “special works”. It's a bit similar with circular saws, where the recommended hook angles range from -10° to more than 20° (ripping), depending on the material being cut and the direction of cut. The most versatile ones (general purpose/combination blades) have hook angles closer to 10°.

View attachment 437265

You can quote and interpret studies, select certain angles or attributes to measure, etc.

Most comments throughout these threads will reflect that too little ‘hook’ in a cutter profile will affect its feeding characteristics; too much will affect its longevity.

I don’t want a flat, vertical edge slamming into wood 20 times per second, as much as I’d like a more gradual entry that also directs the cutter to the corner of the kerf.

Call it a ‘C’, or a ‘J’, or any other letter in any alphabet.

But, again, other folks can sharpen how they prefer.

Philbert

Squish9

Pinnacle OPE Member

- Local time

- 10:49 PM

- User ID

- 28596

- Joined

- Feb 27, 2024

- Messages

- 331

- Reaction score

- 1,468

- Location

- Australia

I think that's where part of the differences come from. This shows the amount of self feeding we get once the wood drys out here. There's no really point in sacrificing durability for self feeding here because it won't do it anyway. This is 36RS, Stihl progressive depth gauge tool on the soft setting.Most comments throughout these threads will reflect that too little ‘hook’ in a cutter profile will affect its feeding characteristics; too much will affect its longevity.

It will cut through there smaller piece because it's less dense.

Here is some 404 semi in the same species of tree that is still green. It will self feed even with the low side plate angle

Squish9

Pinnacle OPE Member

- Local time

- 10:49 PM

- User ID

- 28596

- Joined

- Feb 27, 2024

- Messages

- 331

- Reaction score

- 1,468

- Location

- Australia

The full video has 3 cuts with it both new and sharpened if you would like to see it let me know and I'll post it up.I'd like to see your chains vs the x-cut chain in timed cuts.

Also this is it new vs sharpened 30/60/60 with the husky roller guide. This wood is still green and the chain can self feed. The first video it can't because the wood is dry

chipper1

Here For The Long Haul!

- Local time

- 6:49 AM

- User ID

- 1463

- Joined

- Jun 25, 2016

- Messages

- 6,391

- Reaction score

- 24,031

- Location

- Grand Rapids Mi

Thanks for the videos.I think that's where part of the differences come from. This shows the amount of self feeding we get once the wood drys out here. There's no really point in sacrificing durability for self feeding here because it won't do it anyway. This is 36RS, Stihl progressive depth gauge tool on the soft setting.

It will cut through there smaller piece because it's less dense.

Here is some 404 semi in the same species of tree that is still green. It will self feed even with the low side plate angle

Well, your wood is a lot harder than what we cut here, why didn't you say that before

Didn't see you were down under...

Edit: sorry for doubting you.

Looks like the 404 is cutting great and self feeding as well, I wouldn't complain about that.

Here more hook definitely makes chain cut quicker, although I see your chain is cutting just fine for the species you have there. On the west coast they have some of the species you have(eucalyptus), but here in Michigan we don't have anything as hard as the eucalyptus. On the harder woods we have, 404 is certainly an good option, and semi-chisel if it's dirty at all. I've actually found that some species do well with a 325 chain on a slower/moderately fast saw. I'd guess a 3/8 picco/Lp would do similar, but I haven't tried anything over 14" for comparison. I do have a 18 or 20" 3/8 picco setup I could put on my 261 and try, but I'd need to get @Armbru84 to let me cut some of the wood he's had up on the hill lol.

Squish9

Pinnacle OPE Member

- Local time

- 10:49 PM

- User ID

- 28596

- Joined

- Feb 27, 2024

- Messages

- 331

- Reaction score

- 1,468

- Location

- Australia

We have to do things a little different because we are are upside downThanks for the videos.

Well, your wood is a lot harder than what we cut here, why didn't you say that before.

Didn't see you were down under...

Edit: sorry for doubting you.

Looks like the 404 is cutting great and self feeding as well, I wouldn't complain about that.

Here more hook definitely makes chain cut quicker, although I see your chain is cutting just fine for the species you have there. On the west coast they have some of the species you have(eucalyptus), but here in Michigan we don't have anything as hard as the eucalyptus. On the harder woods we have, 404 is certainly an good option, and semi-chisel if it's dirty at all. I've actually found that some species do well with a 325 chain on a slower/moderately fast saw. I'd guess a 3/8 picco/Lp would do similar, but I haven't tried anything over 14" for comparison. I do have a 18 or 20" 3/8 picco setup I could put on my 261 and try, but I'd need to get @Armbru84 to let me cut some of the wood he's had up on the hill lol.

The 404 semi was doing it easy there in green wood but it works very well. It's dolmar brand Oregon 27X. It's a great chain that comes with a crap factory grind these days

I have run 3/8lp on a 260 and liked it a lot, Stihl used to sell it as a performance cut kit here with a LP bar and 2 chains

chipper1

Here For The Long Haul!

- Local time

- 6:49 AM

- User ID

- 1463

- Joined

- Jun 25, 2016

- Messages

- 6,391

- Reaction score

- 24,031

- Location

- Grand Rapids Mi

Yeah, I bet, seen some of the guys chains there, I wouldn't want to deal with that. Guys say I cut a lot of hard wood, seasoned black locust doesn't come close to what you guys got.We have to do things a little different because we are are upside down

The 404 semi was doing it easy there in green wood but it works very well. It's dolmar brand Oregon 27X. It's a great chain that comes with a crap factory grind these days

I have run 3/8lp on a 260 and liked it a lot, Stihl used to sell it as a performance cut kit here with a LP bar and 2 chains

From what I remember, using the 325 I had a stock 353, so it was pretty slow, but it was about the only thing that self fed into the nasty piece of wood we were cutting. I don't know that we ever figured out what it was, but it was some of the hardest I've ever cut.

Woodwackr

Here For The Long Haul!

- Local time

- 4:49 AM

- User ID

- 28333

- Joined

- Jan 18, 2024

- Messages

- 3,511

- Reaction score

- 16,303

- Location

- ID

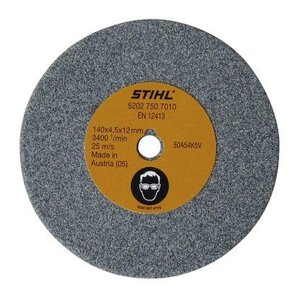

Does anyone know if the Stihl USG will take a 145mm wheel like the Oregon? I know the arbor diameter is 12mm but my CBN wheels all came with adapters from 7/8” to 12 mm so that not an issue. The USG takes a 140mm heel but is there room for a 145?

According to Baltic’s site the 5 3/4” wheels will work

According to Baltic’s site the 5 3/4” wheels will work

Last edited:

- Local time

- 12:49 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,885

- Reaction score

- 59,167

- Location

- Croatia

Worst case You can dress the 145mm wheel down to 140mm.Does anyone know if the Stihl USG will take a 145mm wheel like the Oregon? I know the arbor diameter is 12mm but my CBN wheels all came with adapters from 7/8” to 12 mm so that not an issue. The USG takes a 140mm heel but is there room for a 145?

According to Baltic’s site the 5 3/4” wheels will work

- Local time

- 12:49 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,885

- Reaction score

- 59,167

- Location

- Croatia

Ah, roger that.Cbn wheels…I have several I use on my Ore machine…that is getting very tired…

Who's got an USG to answer the mans question?

How does the guard look like, any chance of modding that if the wheels don't fit?

- Local time

- 12:49 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,885

- Reaction score

- 59,167

- Location

- Croatia

mrxlh

I stayed late and finished!

- Local time

- 5:49 AM

- User ID

- 14780

- Joined

- Dec 2, 2020

- Messages

- 965

- Reaction score

- 4,113

- Location

- Dat Boot

Beak is beak, hook is hook, both are fast. If you look at the new Stihl chain that is faster than square, it is a combination of hook/beak lovechild from hexa and super sharp C.

Woodwackr

Here For The Long Haul!

- Local time

- 4:49 AM

- User ID

- 28333

- Joined

- Jan 18, 2024

- Messages

- 3,511

- Reaction score

- 16,303

- Location

- ID

well, Baltic's site sells the same wheels for Oregon as the Stihl so I'm betting they will fit. They sent the 145x 22s with a 12mm insert to fit either grinder. We shall see next weekQuick Google search.

Seems it is 140mm for the USG

View attachment 437722

And the guard seems to be part of the case.

View attachment 437723

Now, how much wiggle room for a larger OD wheel is under that guard?

SimonHS

Pinnacle OPE Member

- Local time

- 11:49 AM

- User ID

- 14420

- Joined

- Nov 4, 2020

- Messages

- 426

- Reaction score

- 1,818

- Location

- Yorkshire, England

Who's got an USG to answer the mans question?

I've got an old one in bits, in a box, in a shed, under a ton of crap. Give me a month or two and I'll build another shed, so I can move the crap out of the way and measure it.

Wonkydonkey

Plastic member

- Local time

- 11:49 AM

- User ID

- 3189

- Joined

- May 14, 2017

- Messages

- 5,518

- Reaction score

- 25,836

- Location

- Sussex, UK.

I got one in a box here, if you need any measurements..? But just maybe the measurements arnt necessary if I read this correctlyAh, roger that.

Who's got an USG to answer the mans question?

How does the guard look like, any chance of modding that if the wheels don't fit?

well, Baltic's site sells the same wheels for Oregon as the Stihl so I'm betting they will fit. They sent the 145x 22s with a 12mm insert to fit either grinder. We shall see next week

- Local time

- 12:49 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,885

- Reaction score

- 59,167

- Location

- Croatia

Christmas is nearing, get big flat rate shipping boxes, shovel them full with said crapand send them out with a note "Out of coal!"I've got an old one in bits, in a box, in a shed, under a ton of crap. Give me a month or two and I'll build another shed, so I can move the crap out of the way and measure it.