You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another chainsaw dyno...

- Thread starter Red97

- Start date

Yes and no, the brake is 65% activated, but not at 65% capacity, it’s controlled braking power is somewhere around the square of percentage applied voltage, also linearly increasing with rpm.

This 100 amp alternators successfully braked a TM661, I think the excitation voltage was a title higher, but it really brings the load on at 10+ volts excitation to the alternator.

I do have a 180A alternator to fit, I think this might be needed for high torque low rpm saws, I’m not sure if it would regulate the entire power band of a CS1201 or Stihl 090 as it sits, peak power yes, maybe not down to clutch slippage.

I need to step up my water supply to deal with those high tq low rpm saws.

- Local time

- 8:18 AM

- User ID

- 570

- Joined

- Jan 17, 2016

- Messages

- 8,096

- Reaction score

- 51,888

Careful with your water excitation bubI need to step up my water supply to deal with those high tq low rpm saws.

Nutball

Here For The Long Haul!

- Local time

- 7:18 AM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,848

- Location

- Mt. Juliet, TN

How about dyno testing how much power is lost when a saw gets hot. Dyno a saw on the cooler side, then put a good 5min of firewood cutting on it, hook it up to the dyno, and make a 1-2min pull (if the dyno can handle that, or keep it on the full 5 min if it can), then a data acquiring run immediately after. Just to simulate working conditions vs a cookie cutting video. I made a work demo video of a 590 once, and noticed it took a solid 3min of cutting firewood to get it warmed up, then a few more minutes to get it hot. That was almost non stop cutting, but I can't say I noticed much difference in power. Maybe a 10% drop if even that.

Sawrain

Pinnacle OPE Member

- Local time

- 11:18 PM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

How about dyno testing how much power is lost when a saw gets hot.

I have been planning to do this, initially with a ms180, as it can easily be run at full power for extended periods. The idea came to me when I saw a similar 10% difference when setting up my steady state controller.

Last edited:

Maintenance Chief

Disrupting the peace with an old chainsaw

- Local time

- 8:18 AM

- User ID

- 11378

- Joined

- Jan 4, 2020

- Messages

- 4,215

- Reaction score

- 13,795

- Location

- South Carolina

I could hear lazy bastards now , " oh hold on my saw needs to cool down , its loosing 23% power ." Sits down on log stares at cooling saw.

Nutball

Here For The Long Haul!

- Local time

- 7:18 AM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,848

- Location

- Mt. Juliet, TN

Makes me wonder how much power my XS7900 makes, it peaks between 11k & 12k.

Have you every dynoed a cs400?

Have you every dynoed a cs400?

Makes me wonder how much power my XS7900 makes, it peaks between 11k & 12k.

Have you every dynoed a cs400?

No, not done a 400 yet.

Shane¹

Pinnacle OPE Member

- Local time

- 8:18 AM

- User ID

- 15023

- Joined

- Dec 21, 2020

- Messages

- 1,729

- Reaction score

- 5,211

- Location

- Kentucky

Have you ever run a 7900 stock coil vs doing the unlimited 272 coil to see if there is any power gain or loss or just let's you rev the piss out of it? Or see if the power band changes at all?

Have you ever run a 7900 stock coil vs doing the unlimited 272 coil to see if there is any power gain or loss or just let's you rev the piss out of it? Or see if the power band changes at all?

No, I haven't. I have seen good power from limited and unlimited ported saws though. Unless going all out I don't think it is worth the hassle.

Shane¹

Pinnacle OPE Member

- Local time

- 8:18 AM

- User ID

- 15023

- Joined

- Dec 21, 2020

- Messages

- 1,729

- Reaction score

- 5,211

- Location

- Kentucky

Usually a price thing for me. Aftermarket 272 coil can be had for about $10 and swap is fairly easy. Oe coil usually $80+ just was curious if there was a power change both seem to work well just curious to see how the dyno numbers looked if you had already done it.

Dolkitafreak

Dolkita686

- Local time

- 8:18 AM

- User ID

- 7904

- Joined

- Nov 19, 2018

- Messages

- 540

- Reaction score

- 1,795

- Location

- Central Ohio

I think it depends on which coil is on it stock. 64xx saws converted with the 13.5 coil don’t bother me a bit, but I don’t like the 12.8 coils at all, too low imo!No, I haven't. I have seen good power from limited and unlimited ported saws though. Unless going all out I don't think it is worth the hassle.

- Local time

- 8:18 AM

- User ID

- 2523

- Joined

- Jan 24, 2017

- Messages

- 4,960

- Reaction score

- 22,966

- Location

- Berkshire County, Massachusetts

Joe can simulate extended run times if his water supply is good...effectively working, loading, and heat soaking the saw.How about dyno testing how much power is lost when a saw gets hot. Dyno a saw on the cooler side, then put a good 5min of firewood cutting on it, hook it up to the dyno, and make a 1-2min pull (if the dyno can handle that, or keep it on the full 5 min if it can), then a data acquiring run immediately after. Just to simulate working conditions vs a cookie cutting video. I made a work demo video of a 590 once, and noticed it took a solid 3min of cutting firewood to get it warmed up, then a few more minutes to get it hot. That was almost non stop cutting, but I can't say I noticed much difference in power. Maybe a 10% drop if even that.

I think it depends on which coil is on it stock. 64xx saws converted with the 13.5 coil don’t bother me a bit, but I don’t like the 12.8 coils at all, too low imo!

Yeh, the 13.5 is handy for sure

markds2

Here For The Long Haul!

- Local time

- 2:18 AM

- User ID

- 6804

- Joined

- Jul 22, 2018

- Messages

- 1,068

- Reaction score

- 6,439

- Location

- Nelson, New Zealand

Awesome work Joe, very, very interesting, especially to me. If you remember, you dynoed my DCS6401 (with a 7910 top end) back in March last year after Kevin @huskihl ported it - we tried it with and without the Poleman modified carb? This is before it got sent all the way out to NZ

Sawrain

Pinnacle OPE Member

- Local time

- 11:18 PM

- User ID

- 2614

- Joined

- Feb 11, 2017

- Messages

- 304

- Reaction score

- 1,275

- Location

- South.

How about dyno testing how much power is lost when a saw gets hot. Dyno a saw on the cooler side, then put a good 5min of firewood cutting on it, hook it up to the dyno, and make a 1-2min pull (if the dyno can handle that, or keep it on the full 5 min if it can), then a data acquiring run immediately after. Just to simulate working conditions vs a cookie cutting video. I made a work demo video of a 590 once, and noticed it took a solid 3min of cutting firewood to get it warmed up, then a few more minutes to get it hot. That was almost non stop cutting, but I can't say I noticed much difference in power. Maybe a 10% drop if even that.

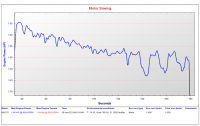

MS170, idle warm up for 30 seconds, then this dyno run of 2 minutes, 40 seconds at 9000rpm full load.

I would have gone for longer but my exhaust gas temp probe insulation gasket failed, I'll put a chart of temps up later, software not playing the game atm, peaked at 920F though.

I need to get an isolated/insulated probe instead of having to electrically isolated this one at the mount.

Thought I would start with a small saw.

Last edited:

Nutball

Here For The Long Haul!

- Local time

- 7:18 AM

- User ID

- 7732

- Joined

- Oct 31, 2018

- Messages

- 4,284

- Reaction score

- 11,848

- Location

- Mt. Juliet, TN

Looks like some big dips in the curve toward the end, I wonder if it was overheating, cooling off, then overheating again? Or just a quirk in the rpm regulator?

Similar threads

- Replies

- 13

- Views

- 2K