- Local time

- 8:05 AM

- User ID

- 714

- Joined

- Jan 28, 2016

- Messages

- 4,123

- Reaction score

- 29,465

- Location

- Dike, Iowa

My 090 cut well also but realize they’re not as fast as a 125 Mac but not way behind either. Sold the 090 because it was just to rough on the hands to use with no av for any length of time. Now I’m down to an 075 and 076 super for my big large mount stihls. No they aren’t an 090 but much nicer to run.The CP125 is a pretty capable saw, that's Don Lane's (sawfun) saw with a 48" bar tackling a 48" diameter oak.

View attachment 470552

Mark

I figured 3 years was verging on a bit too long to just lap a clutch 'n' snug it down. Bugger is the clutch nut rounded off when I was installing it, but since the clutch is good and snug I'll worry about that later.Heck yeah Mr. D - awesome!

Like woodslasher my saw needs a serious bite, had a taste but bar/chain not cutting straight so worked on it and changed carb to a 090. Rumbles. Have questions should have asked a long time ago. Does the filter get placed under the tank liner in a 797 ?. Finishing a grommet set up for fuel and want to get the run time it should have before done is done.

The other Question I have , is it all my gas cap allowing and causing the gas to continue to run through the carb and fill air box when off ?

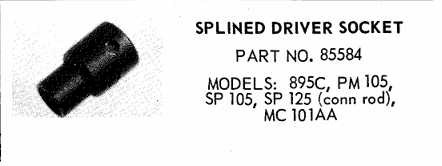

Do you have a part number or a saw that uses it that I can look up on an IPL to see what the part is?Does anyone know of a source for the special socket/splined Mcculloch connecting rod bolts?

Does anyone know of a source for the special socket/splined Mcculloch connecting rod bolts?

You do need the special socket for the original Mac bolts. New nos bolts can be had as I have

found a few on ebay and keep a couple sets in stock. Terry Ives in Ca. uses allen head screws

with what he says better results as they don't break like the Mac bolts, But he is in the karting

world not the chainsaw world we are in. Not sure which screws he uses as I have never needed

them.

I have placed four different carbs on . Three of them have all consistently behaved the same, including the new 090 carb just bought new. I cleaned out cap and replaced valve and believe it to be working.If your airbox is filling with fuel, then it's likely the inlet needle not closing. It could be that the inlet needle lever isn't adjusted correctly or that something is holding it open. Old diaphragms can get sucked in and hold the lever down which keeps the needle open. The Mac gas caps originally had a check valve which allowed the tank to build pressure but disallowed a vacuum. So your gas cap shouldn't be an issue unless the needle is being held open. Of course, a lot of check valves in gas caps have rotted due to the passage of time so most saws aren't building much pressure in their tanks.

I have placed four different carbs on . Three of them have all consistently behaved the same, including the new 090 carb just bought new. I cleaned out cap and replaced valve and believe it to be working.

No just a steady second and a half wait for a tear drop amount to come from the back. Thankfully saw sits with a degree back so doesn’t go down the manifold. I am just going to disconnect fuel line from tank after use if keeping gas in tank.Then maybe the fuel line barb is leaking?

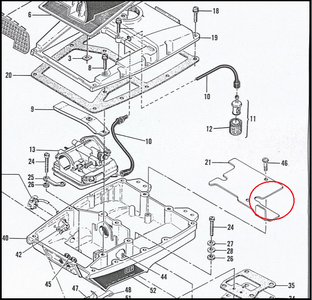

I would guess that it would snake around the right side of the liner (circled in red) and the fuel filter would rest underneath it. This to me would seem to allow the filter to move around a bit, but not bang around the fuel tank and allow it to help maximize use of fuel in the tank rather than sitting on top and not being able to get to the rest without potentially putting the saw on its side.Does it go under fuel liner, my brain says no because it is there to protect tank from the weighted filter, just so much gas not able to be used confuses me.

Yes, that is how it appears to me. It has been two years since I began this project , wish I remembered how it came out. Almost sure it was on top though. Finished the saw yesterday and am happy with how well the tank is holding as well as grommet with seal all. First time I’ve completely filled the tank. Problem with slow leak fixed. The valve was completely shut, gave it a squeeze to pucker and no more steady drip.I would guess that it would snake around the right side of the liner (circled in red) and the fuel filter would rest underneath it. This to me would seem to allow the filter to move around a bit, but not bang around the fuel tank and allow it to help maximize use of fuel in the tank rather than sitting on top and not being able to get to the rest without potentially putting the saw on its side.

View attachment 470659

Yes, I do the same thing, wishing I had taken more photos while pulling the saw apart! Glad to hear that your leak is fixed and that the saw is working as it should!!Yes, that is how it appears to me. It has been two years since I began this project , wish I remembered how it came out.