Squareground3691

Here For The Long Haul!

- Local time

- 11:16 PM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,307

- Reaction score

- 15,961

- Location

- New England

We’re Terry (Legend) Ives, Lol

I talked to Terry a few days ago. He's 83....and doesn't seem like he's ready for retirement yet. I'd be happy to still be in the game at 83.We’re Terry (Legend) Ives, Lol

I talked to Terry a few days ago. He's 83....and doesn't seem like he's ready for retirement yet. I'd be happy to still be in the game at 83.

Can’t even imagine how many Mac’s he put together and developed,I talked to Terry a few days ago. He's 83....and doesn't seem like he's ready for retirement yet. I'd be happy to still be in the game at 83.

Ya .003–.004 , some of the kart forums state .0075-.0100 for race clearance. At .003 I like and extra long break in and letting it idle and get really warm before any cuts. I usually let my 101’s idle for at least a half hour with some revs for break-in before I make any cuts breaking that up several times

I'm gonna split the difference. .004" is the target. LOLI've been going .0045-.0055" on mine, depending on bore size. All of my recent builds have been larger bore sizes (0.030"+). I went .0055" on my .060" over 101b in my dad's old saw. I'll be building an .080" over 125 iron-bore motor this summer and will go probably .0055-60" on that one.

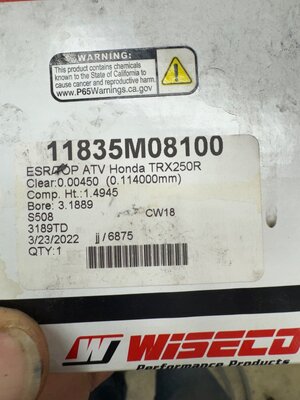

I have had Terry set up a few of mine a little tighter. Than his usual. And they have been good. All of my bigger bore fordged pistons quad stuff runs a lot tighter, blaster 2mm overbore pistons that are 68mm need .002 clearance and my 81mm pistons need .0045,I've been going .0045-.0055" on mine, depending on bore size. All of my recent builds have been larger bore sizes (0.030"+). I went .0055" on my .060" over 101b in my dad's old saw. I'll be building an .080" over 125 iron-bore motor this summer and will go probably .0055-60" on that one.

Usually a forged piston requires more clearance than a cast piston. .002 sure seems really tight for a forged slug.....but I think Wiseco knows more than Randyco. LOLI have had Terry set up a few of mine a little tighter. Than his usual. And they have been good. All of my bigger bore fordged pistons quad stuff runs a lot tighter, blaster 2mm overbore pistons that are 68mm need .002 clearance and my 81mm pistons need .0045,

I just think some of the clearance is excessive. I know they run with it, but I think it’s mainly from inadequate warm-up timeView attachment 456198View attachment 456199

Yeah, I don’t know either. I just tried to follow the best advice I have, and experience.Usually a forged piston requires more clearance than a cast piston. .002 sure seems really tight for a forged slug.....but I think Wiseco knows more than Randyco. LOL

Good prep work pays off,Yeah, I don’t know either. I just tried to follow the best advice I have, and experience.

Been running the tight end of Waco specs for a long time now and have been very happy, once I learn proper warm-up time the results have been excellent.. I use the blaster piston in banshees for years now, made 109hp with 2 at 10,000 rpm and am running a 78mm bore at .0035 and it has lots of hours on it

Nothing beats experience.....and you've gotten it.Yeah, I don’t know either. I just tried to follow the best advice I have, and experience.

Been running the tight end of Waco specs for a long time now and have been very happy, once I learn proper warm-up time the results have been excellent.. I use the blaster piston in banshees for years now, made 109hp with 2 at 10,000 rpm and am running a 78mm bore at .0035 and it has lots of hours on it

Is this for initial use of a new piston and rings or normal warm up for use? I like how the people on YouTube fit in a new piston and then gun it within seconds of starting it...lolI usually let my 101’s idle for at least a half hour with some revs for break-in before I make any cuts breaking that up several times

There’s always more learn! Wiesco’s also tapers their pistons, not sure on all the Mac and all of the Burris pistonsNothing beats experience.....and you've gotten it.

Makes sense. When I replace a piston or piston and cylinder, I let the saw idle through a tank of gas first.I get at least a half an hour of break in warm-up

Good plan.Wouldn’t hurt to talk to Terry again and get his opinion! He is definitely the authority on it