lehman live edge slab

Live Action

- Local time

- 11:28 AM

- User ID

- 3953

- Joined

- Sep 2, 2017

- Messages

- 4,920

- Reaction score

- 16,818

- Location

- Mn

That one looks to be in really good shape and would clean up well. Looks to be a lot less metal rot than on my 200!This is it if Randy can use and it will work.

I wonder if the plunger seals for the manual oiler are flexing and letting air byI need some help here in figuring out why the manual oiler won't work.I pulled the cover off the oil tank yesterday & the automatic pump was securely in place & the oil pick up seemed to be in good condition with a clear pick up screen.When I push the oiler button I get very little oil if any at the pad & it's sucking air from somewhere as I'll get air bubbles at the pad.

You are a absolute wealth of knowledge my friend.Ed - I will presume we are still talking about the PM800?

There are 2 check valves in the oiler system, one is the disc under the manual pump and the other is a check ball (and spring) in the automatic oiler. If either of those are not functioning the oiler will not work.

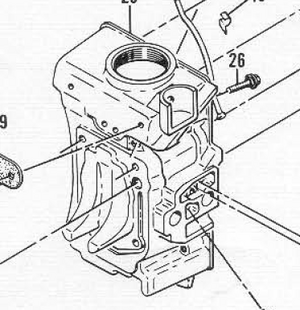

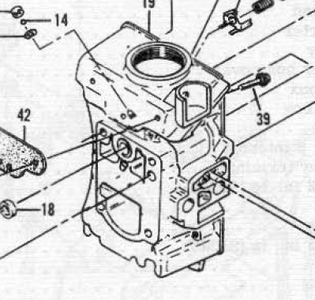

To access the disc check valve in the manual oiler the tank has to come off, cover off the oil tank, and remove the two screws holding the manual oil pump down. One is tapped into the housing, the other has a nut (11/32") inside the tank. There were two different discs used and they have to work with the flange on the oil pick up hose. The thicker phenolic disc works with the thinner flange, the thinner aluminum disc work with the thicker flange.

View attachment 455355

Thin flange

View attachment 455356

Thick flange

View attachment 455357

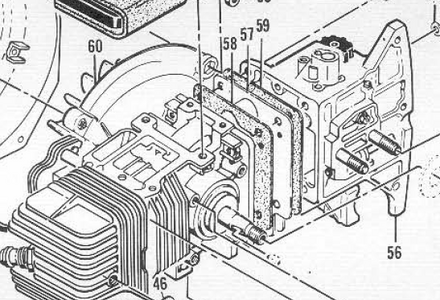

To access the ball check valve in the automatic oiler you have to remove the automatic oil pump from the tank (should be one screw and the spring clip on a PM800). On the older pumps you could remove a screw from the top of the pump and take everything out. This is another version of a spring clip that attached to the top of the automatic pump to help press it firmly against the seal (gasket) at the mounting surface.

View attachment 455353

On the newer pumps there is no access to the ball and spring so you just have to shoot some brake or carburetor cleaner in the ports and the steel guide in the pump and hope it unsticks the ball.

Test the check valve by putting some oil in the inlet hole and working the piston manually. If everything is O.K. you will see the oil go down the inlet and back up the outlet. Inlet is on the left, outlet on the right. You can also test the check valve by applying pressure to the outlet side, is should hold 5-7 PSI, but just holding pressure will not tell you if the ball is stuck. If you apply pressure to the inlet side it will push the piston out.

View attachment 455354

Mark

Good Info Mark!Ed - I will presume we are still talking about the PM800?

There are 2 check valves in the oiler system, one is the disc under the manual pump and the other is a check ball (and spring) in the automatic oiler. If either of those are not functioning the oiler will not work.

To access the disc check valve in the manual oiler the tank has to come off, cover off the oil tank, and remove the two screws holding the manual oil pump down. One is tapped into the housing, the other has a nut (11/32") inside the tank. There were two different discs used and they have to work with the flange on the oil pick up hose. The thicker phenolic disc works with the thinner flange, the thinner aluminum disc work with the thicker flange.

View attachment 455355

Thin flange

View attachment 455356

Thick flange

View attachment 455357

To access the ball check valve in the automatic oiler you have to remove the automatic oil pump from the tank (should be one screw and the spring clip on a PM800). On the older pumps you could remove a screw from the top of the pump and take everything out. This is another version of a spring clip that attached to the top of the automatic pump to help press it firmly against the seal (gasket) at the mounting surface.

View attachment 455353

On the newer pumps there is no access to the ball and spring so you just have to shoot some brake or carburetor cleaner in the ports and the steel guide in the pump and hope it unsticks the ball.

Test the check valve by putting some oil in the inlet hole and working the piston manually. If everything is O.K. you will see the oil go down the inlet and back up the outlet. Inlet is on the left, outlet on the right. You can also test the check valve by applying pressure to the outlet side, is should hold 5-7 PSI, but just holding pressure will not tell you if the ball is stuck. If you apply pressure to the inlet side it will push the piston out.

View attachment 455354

Mark

Well howdy Max.Many of you by now know of my history/journey with McCulloch saws. Over the years I have met many great folks in the saw world. One of those is Mark Heimann. After a few years on phone conversations, emails and so forth I made my first trip out to see Mark in the late summer of 2023. It was a wonderful visit. Seeing the museum and talking to Mark about saws in person is an experience any McCulloch enthusiast should have. Before I headed east for home, I noticed a DE 80 on his sell shelf. The crankcase was gray, and I asked Mark if it was what I thought, he confirmed it. A PM 8200 block under a DE80 tank. I told Mark I had all the parts to take the saw and make the PM 8200 engine back into an original full-grown PM 8200, as well as make the DE 80 parts back into a full-grown DE 80. A deal was struck. The saw came to live in Virginia. I sat in in a shelf and there it sat. I never dug out my used spare parts to piece it back into a PM 8200. Fast forward to last fall on eBay I saw a very clean PM 8200 for sale with a bad cylinder. She was cosmetically prettier than the sum of my used parts, so I bought her, and she came to Virginia to sit on a shelf (y’all see a pattern here? lol). Last Saturday I tore the roached PM 8200 apart. It was BAD inside. The worst 82cc I have seen yet. Massive air leak from the intake boot, she got HOT and ate herself alive. Sunday Alan came over to help me with some stuff and we found time to take the DE80/PM 8200 from Mark apart and place the engine from it into the other PM 8200. Its back together and alive as a fully original PM 8200 now. The DE 80 parts will be used to transform a very ugly but very strong running PM 805 into a full-grown DE 80. Maybe it will not take another two years to get to that one lol. Only 14 more saws left to fix if I don’t add more!

View attachment 455535View attachment 455536View attachment 455537View attachment 455538View attachment 455539

Yeah me also. It had ZERO compression a fly could land on the flywheel at 9 or 3 position and the saw would likely rotate it to 6pm lolWell howdy Max.

That might be the worst piston I've ever seen.