Dream

Mastermind Approved!

- Local time

- 8:51 PM

- User ID

- 7152

- Joined

- Aug 27, 2018

- Messages

- 8,422

- Reaction score

- 45,976

- Location

- Elberton, GA

So ive been wondering this for awhile, and I'm sure some of you have probably thought in the same direction.

If one wanted to "hot rod" a 10 series Mac, would it be possible to take an approach that might solve two problems at once?

Problem 1.

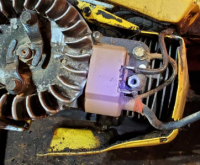

Clamshell design that makes it difficult to decrease "squish" without machining the crank bearing pockets in the cylinder.

Problem 2.

Piston wrist pin bearings that wreck the cylinder if they fail.

I'm wondering if a piston with a single wrist pin bearing and a different rod could be used to get the compression "squish" to around .020".

I know, it would take some fairly precise machine work, but could the crank pin be bored out of the crank, thereby making it a 3 piece crank like most modern saws?

If a rod/piston combination could be sourced to do that, one could then port the saw to do whatever they wanted performance-wise. Higher torque/speed/"horsepower".

Im not saying they are in desperate need of that at all, I'm extremely impressed by how most of mine run and hold up to modern saws.

I'm just wondering if they could be improved upon, or would it be a waste of time and money for a marginal gain.

If one wanted to "hot rod" a 10 series Mac, would it be possible to take an approach that might solve two problems at once?

Problem 1.

Clamshell design that makes it difficult to decrease "squish" without machining the crank bearing pockets in the cylinder.

Problem 2.

Piston wrist pin bearings that wreck the cylinder if they fail.

I'm wondering if a piston with a single wrist pin bearing and a different rod could be used to get the compression "squish" to around .020".

I know, it would take some fairly precise machine work, but could the crank pin be bored out of the crank, thereby making it a 3 piece crank like most modern saws?

If a rod/piston combination could be sourced to do that, one could then port the saw to do whatever they wanted performance-wise. Higher torque/speed/"horsepower".

Im not saying they are in desperate need of that at all, I'm extremely impressed by how most of mine run and hold up to modern saws.

I'm just wondering if they could be improved upon, or would it be a waste of time and money for a marginal gain.