You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Metalworking Thread

- Thread starter davidwyby

- Start date

Squareground3691

Here For The Long Haul!

- Local time

- 9:26 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,291

- Reaction score

- 15,862

- Location

- New England

Yup , it works well. factory fresh,If it works, go for it.

I have junked a couple clutches & drums that were fried on used saw purchases.

Although, saws that clutches can still be had new.

Squareground3691

Here For The Long Haul!

- Local time

- 9:26 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,291

- Reaction score

- 15,862

- Location

- New England

- Local time

- 3:26 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,043

- Location

- Croatia

That is one expensive piece of hardware!!!One big chunk of carbide, 2.5” at top and 1 “at bottom, 1.25 “ shank , will become a turbine blade cutter when finished,View attachment 442253

Looks beautiful too.

Squareground3691

Here For The Long Haul!

- Local time

- 9:26 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,291

- Reaction score

- 15,862

- Location

- New England

Yes it’s only half way done , and very expensive, lol

- Local time

- 3:26 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,043

- Location

- Croatia

Sooo, it is only half price now instead later when it's all done?!Yes it’s only half way done , and very expensive, lol

- Local time

- 6:26 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,664

- Reaction score

- 38,343

- Location

- Extreme Southeast CA

- Local time

- 3:26 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,043

- Location

- Croatia

- Local time

- 6:26 AM

- User ID

- 5156

- Joined

- Jan 24, 2018

- Messages

- 9,664

- Reaction score

- 38,343

- Location

- Extreme Southeast CA

- Local time

- 3:26 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,043

- Location

- Croatia

Does this count as metal working?

30+ year old hatchet, sharpening through grinding removed a lot of metal over the decades.

This is my attempt to restore at least some of the blades life.

That is a 12.9 grade M20 bolt piece.

Flux wire welded, cheap supermarket welder - truth be told it came out better than I expected.

I am in the process of grinding off all the excess steel with my 9" angle grinder.

If this works out I will have restored about an 1/2" of blade.

30+ year old hatchet, sharpening through grinding removed a lot of metal over the decades.

This is my attempt to restore at least some of the blades life.

That is a 12.9 grade M20 bolt piece.

Flux wire welded, cheap supermarket welder - truth be told it came out better than I expected.

I am in the process of grinding off all the excess steel with my 9" angle grinder.

If this works out I will have restored about an 1/2" of blade.

Last edited:

Al Smith

Here For The Long Haul!

- Local time

- 9:26 AM

- User ID

- 537

- Joined

- Jan 14, 2016

- Messages

- 6,679

- Reaction score

- 14,913

- Location

- North western Ohio

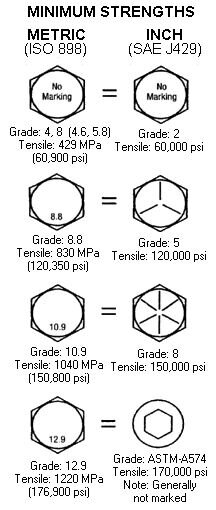

If I'm not mistaken 12.9 metric is about the same as SAE grade 8 . You cut cut it with carbide and often with ceramic tooling but it's tough stuff .I've seen extremely hard steel cut with carbide,the metal and the tool glows cherry red even with coolant .Camshaft lobes before they were finished ground .

- Local time

- 3:26 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,043

- Location

- Croatia

SAE Grade to is "about" ISO 10.9 gradeIf I'm not mistaken 12.9 metric is about the same as SAE grade 8 . You cut cut it with carbide and often with ceramic tooling but it's tough stuff .I've seen extremely hard steel cut with carbide,the metal and the tool glows cherry red even with coolant .Camshaft lobes before they were finished ground .

To my understanding there is no SAE "bolt" grade that matches ISO 12.9!

See my signature.

And there is such a thing as ISO 14.9 grade for special applications to boot.

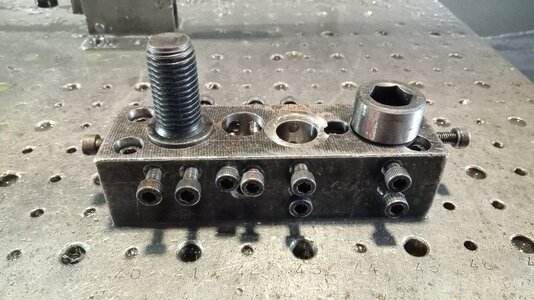

I am making custom chainsaw tools out of 12.9 grade bolts, I process them with Solid-Carbide drill & mill bits.

Even with maxed out liquid cooling and very conservative tooling parameters the mill bits take a beating and dull fast.

I am impressed with 12.9 grade steel properties, I love this stuff being a metal worker by trade!

Squareground3691

Here For The Long Haul!

- Local time

- 9:26 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,291

- Reaction score

- 15,862

- Location

- New England

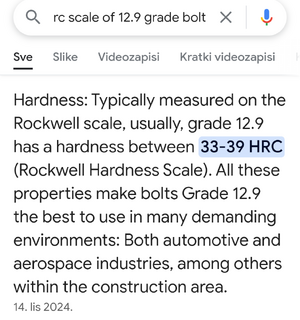

What’s the RC scale on those bolts ?SAE Grade to is "about" ISO 10.9 grade

To my understanding there is no SAE "bolt" grade that matches ISO 12.9!

See my signature.

And there is such a thing as ISO 14.9 grade for special applications to boot.

I am making custom chainsaw tools out of 12.9 grade bolts, I process them with Solid-Carbide drill & mill bits.

Even with maxed out liquid cooling and very conservative tooling parameters the mill bits take a beating and dull fast.

I am impressed with 12.9 grade steel properties, I love this stuff being a metal worker by trade!

- Local time

- 3:26 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,857

- Reaction score

- 59,043

- Location

- Croatia

Squareground3691

Here For The Long Haul!

- Local time

- 9:26 AM

- User ID

- 16376

- Joined

- May 1, 2021

- Messages

- 3,291

- Reaction score

- 15,862

- Location

- New England

Grade 8 is the same RC scale as 12.9If RC is the same as HRC, according to Google:

View attachment 447835

Although Wikipedia & Google say that 12.9 grade bolts can be tempered making their outer surface much harder, and I can say I have had noticeable tooling wear differences between different brand bolts.

Similar threads

- Replies

- 78

- Views

- 9K