- Local time

- 6:53 AM

- User ID

- 5961

- Joined

- Apr 21, 2018

- Messages

- 3,106

- Reaction score

- 10,972

- Location

- Momence,IL

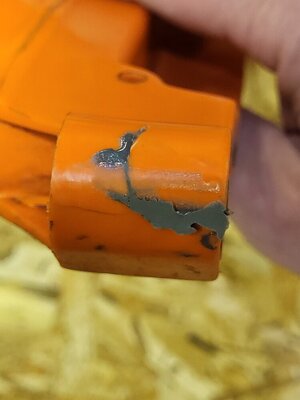

So as I'm going through old 261/2 parts that I've acquired over the years I came across a few busted tanks and a once repaired tank(not by me). The PO made a solid repair, even though not so pretty, but fully functional and got his saw back to cutting. It peaked my interest and I wanted to do one myself. These tanks have been NLA for quite some time now and it's silly to me to call it trash when it can be revived. Seems the front AV pocket is prone to cracking out, I'm guessing if the bar gets pinched and ya start to do some yanking, it is very possible. Spring on one side rubber on the other. Don't wanna call it a bad design but I think it is. U have a fastened side and a floating side. For giggles I took out my 262 and did a Lil tweeking on it, just the powerhead.... Ya, add a 20" bar and a bad attitude and I could see how this thread got started. Here's some pics of the repaired tank. Then I'll get into my repair. This is just kinda an informational piece, take it and use it as you wish. I didn't reinvent the wheel, I seen it done already and copied it. I do think this could help keep the Ole 261/2's alive alot longer, and who doesn't want that?

This repair was done with 1/8" steel and took alot more persuasion than what I did. Solid as a rock but maybe a Lil overkill. Even with the added thickness and screw on the top side(up against the case) there was just a small amount of powder rubbed off the case. More than enough room for this fix to be functional without being detrimental to other parts.

This repair was done with 1/8" steel and took alot more persuasion than what I did. Solid as a rock but maybe a Lil overkill. Even with the added thickness and screw on the top side(up against the case) there was just a small amount of powder rubbed off the case. More than enough room for this fix to be functional without being detrimental to other parts.