- Local time

- 4:47 PM

- User ID

- 1204

- Joined

- Apr 28, 2016

- Messages

- 14,897

- Reaction score

- 59,222

- Location

- Croatia

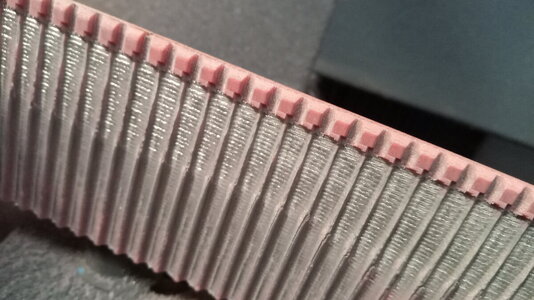

Well, that belt didn't fail - yet!

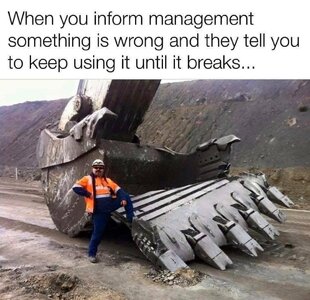

But they killed a different mill.

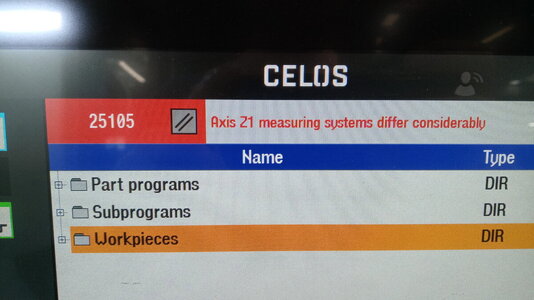

It wouldn't calibrate on Monday due to a C-axis clamp/unclamp error (hydraulic).

They messed with it till the overload switch popped, then kept messing with the machine whilst flipping the switch back everytime it would pop.

In an attempt to force the machine into calibrating they manually/forcefully "rocked" the C-axis.

After about 7 hours of messing with the machine it somehow passed calibration and became functional.

Well, good for my employer I guess?!

Although, in order to keep the machine calibrated they left it on continuously, even though it didn't get ran in the PM nor nightshift.

Whatever the initial issue was caused the bursting of a pressure hydraulic oil line on Wednesday.

And still the machine did not get shut down as it was deemed economical to refill whatever oil is lost just to keep the mill running FOR ONE 8 HOUR SHIFT A DAY.

Eventually the leak got so severe the entire content of the main tank spilled.

The mill is now 100% non functional and to replace the oil line the C-axis (which is the table) needs to be pulled out.

Oh, and no one bothered to prevent nor contain the spill - those are gallons of hydraulic oil!

Nevermind the couple rags.

But they killed a different mill.

It wouldn't calibrate on Monday due to a C-axis clamp/unclamp error (hydraulic).

They messed with it till the overload switch popped, then kept messing with the machine whilst flipping the switch back everytime it would pop.

In an attempt to force the machine into calibrating they manually/forcefully "rocked" the C-axis.

After about 7 hours of messing with the machine it somehow passed calibration and became functional.

Well, good for my employer I guess?!

Although, in order to keep the machine calibrated they left it on continuously, even though it didn't get ran in the PM nor nightshift.

Whatever the initial issue was caused the bursting of a pressure hydraulic oil line on Wednesday.

And still the machine did not get shut down as it was deemed economical to refill whatever oil is lost just to keep the mill running FOR ONE 8 HOUR SHIFT A DAY.

Eventually the leak got so severe the entire content of the main tank spilled.

The mill is now 100% non functional and to replace the oil line the C-axis (which is the table) needs to be pulled out.

Oh, and no one bothered to prevent nor contain the spill - those are gallons of hydraulic oil!

Nevermind the couple rags.