- Local time

- 6:06 PM

- User ID

- 4

- Joined

- Dec 3, 2015

- Messages

- 52,954

- Reaction score

- 352,753

- Location

- Banner Springs Tennessee

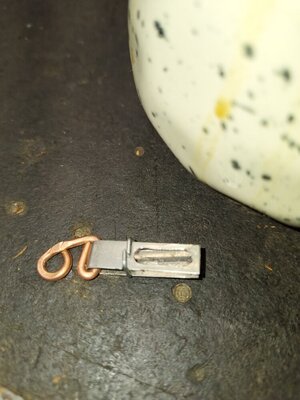

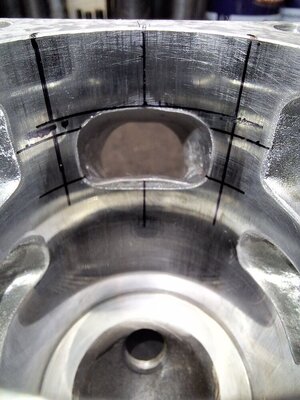

The 288 piston seems to be the best.So... But to summarize thus far. Yes it can be done... Should it? I ain't know. Not yet anyway. Even if it ever makes a sh*t ton of power (which is up to you guys, especially Doc), most would consider this a PITA. 82.45CC'S, well ported, should hang with a 500i and then some of it won't be worth it to most of ya. Myself, if I get it close, I'll enjoy the cool factor enough to justify it. But this should have been Doc's build, so any fruits will be butter sweet unless there's a bushel of them. I did learn one thing however. I bet any one of us would benefit from trying this slug in a 660. It would allow for squish to be cut without lowering cylinder. Transfer could be left tighter, and intake later. So that's on my mind. I bought 3 more of these slugs incase there's a famineView attachment 411133